ROTOR SYSTEM MAINTENANCE

Organizational maintenance of the helicopter

rotor system includes periodic inspection, lubrica-

tion, rigging, and adjustment. Organization

maintenance includes the cleaning of the rotary

wing and rudder blades, and the removal and

replacement of malfunctioning components.

Vibration of the rotary mechanisms can result

in work hardening of metals and later fatigue

failure. Nondestructive testing of special parts of

the rotary wing and the rotary rudder at specified

intervals is necessary to prevent failures. The

rotary wing head and rotary rudder assemblies are

high-time removal items, as listed in the periodic

maintenance information cards (PMIC).

Cleaning of the rotary wing and rotary rudder

should be accomplished as necessary, using

approved cleaners mixed with water. The concen-

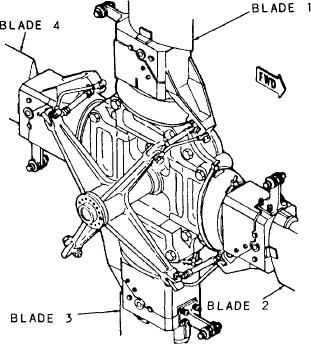

Figure 7-20.-Rotary rudder head.

tration of the mixture will vary, depending on the

surface condition.

is necessary when the blades, the main gearbox,

or the main rotor head assembly have been

WARNING

replaced. Unless the blades are in proper track,

vibrations will occur in the helicopter with every

Both the rotary wing and rudder blades

revolution of the main rotor. At high rpm settings,

have areas that are joined by bonding

these vibrations could cause serious structural

adhesives. Never use solvents or cleaners

damage.

not specifically authorized in the MIM.

Never use lacquer thinner, naphtha, carbon

Tracking the blades is necessary to be sure that

tetrachloride, or other organic compounds

all of the blades rotate in the same horizontal

for cleaning in these bonded areas. The

plane (track). This is accomplished by pretrack

bonding will be weakened by the solvent

rigging of the rotary wing head and by the use

and may result in blade failure.

of pretracked blades.

Although ADs remove and replace rotary

Pretrack rigging of the rotary wing head

wing parts, the airframes work center normally

involves adjusting the pitch control rods until

performs the rigging checks. Rigging checks and

an exact sleeve angle (within 1 minute) is

adjustment involve coordinating the cyclic pitch

attained on all sleeve spindles. When this exact

control stick, collective pitch control stick, and

angle is established, a micrometer type decal

pedal positions with the correct rotary wing and

is affixed on the adjustable pitch control

rotary rudder blade angles. Rigging checks are

rods. The decal becomes a permanent reference

necessary to ensure that the flight controls are

at the overhaul activity. A pretrack number

operating under normal friction loads. At the

is stenciled on each blade at manufacture or

completion of rigging, a flight test is performed

overhaul, based on the effective angle of the

by a qualified pilot. This includes a check of blade

blade. Install any pretracked blade on the

tracking.

helicopter simply by setting the adjustable

pitch control rod to the pretrack number stenciled

ROTOR BLADE TRACKING

on the blade. The blade tracking is then checked

with either Strobex or electronic tracking equip-

You should perform blade tracking whenever

ment.

the helicopter has been rerigged. Blade tracking

7-23