The power supply is self-contained. It is

pump, and lines. Eventually the stand will fail,

designed to check the performance and character-

either jamming or collapsing.

i s t i c s of aircraft hydraulic systems. The

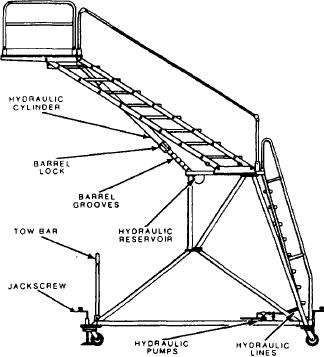

B-2 Workstand

A/M27T-5 is capable of performing the follow-

ing functions:

A type of workstand in common use is the B-2,

1. Delivering hydraulic fluid at controlled

shown in figure 3-15. The B-2 consists basically

pressures. This enables operation of the aircraft's

of a fixed height, 10-foot lower structure; a

hydraulic system without the need to start the air-

variable height upper structure; and a manual

craft's engines.

pump-actuated hydraulic system for raising and

2. Testing the flow rate of aircraft hydraulic

lowering the upper structure. The upper structure

systems.

includes a work platform with guardrails and steps

with handrails. The platform and steps, because

3. Testing the aircraft hydraulic system and

components for leakage or malfunction.

of parallelogram linkage, stay horizontal

4. Flushing and refilling aircraft hydraulic

throughout their upward or downward travel. The

systems with MIL-H-83282 hydraulic fluid filtered

lower structure includes fixed steps and handrails,

to 3-micron absolute.

a tow bar, and four free-swivel caster wheels for

mobility. Each caster is equipped with a safety

locking device containing a spring-loaded pin,

which snaps into notches on the caster pivot axle

NONPOWERED SUPPORT

EQUIPMENT

to lock the caster swivel. The lower structure also

includes four immobilizing jacks with baseplates.

So far we have discussed only powered SE.

The jack plates press against the ground and act

This portion of the text will discuss nonpowered

as brakes, but not supports, for the structure. You

may find some B-2 stands with the foot-lever

support equipment. Nonpowered SE is all the

brakes (like the B-4A and B-5A) instead of the

equipment that has no engine or motor installed

to supply power for equipment operation.

jackscrews.

The height range for the B-2 work platform

MAINTENANCE PLATFORMS

is from 13 feet to 20 feet. Overall height, including

the 3 1/2-foot guardrails, is 16 1/2 feet lowered

Maintenance stands, platforms, or workstands

(the names are commonly interchangeable) give

us a means to reach parts of the aircraft we can't

safely reach or work on from the ground. There

are a large variety of types and models. Some of

the stands are common SE used on almost any

type of aircraft. Others are very large stands used

only at shore activities or on one specific type of

aircraft.

Most adjustable aircraft maintenance plat-

forms are hydraulically operated. A platform and

ladder assembly are mounted on a caster-equipped

base. This enables maintenance personnel to safely

work at heights from 3 feet to a maximum of 20

feet, depending on the stand selected. Since the

design, use, safety precautions, and procedures

are generally very similar, we will cover only a

few of the more common stands.

Most maintenance workstands become de-

fective through abuse and lack of care. Most small

stands are designed to hold 500 pounds safely.

Overloading the stand can cause some part of the

platform structure to bend. That generally causes

the lift structure, or steps to bind. That, in turn,

Figure 3-15.-B-2 maintenance platform.

puts abnormal pressure on the hydraulic cylinder,

3-13