The primary components of the unit are a

and installation in some aircraft. See figure 3-21.

large solution tank, two air cylinders, a work

Prior to using the bomb hoist, a PREOPERATIONAL

platform with guardrail, four spray applicator

inspection, which includes checking the cable

wand assemblies, and the trailer.

for frayed or broken strands, must be con-

ducted. Always be sure that the hoist load

test date is current and that the cable is routed

properly.

WARNING

A drawbar at the front of the trailer

provides towing and steering capabilities.

WARNING

It also incorporates a spring loaded "dead-

man" brake. If the drawbar is released

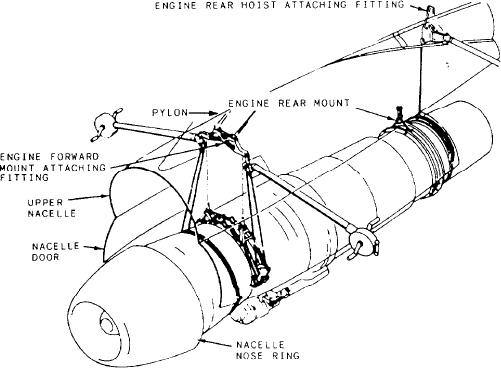

Never leave an engine unattended while it

from the horizontal towing position, it

is being supported by hoists. Never work

returns to the vertical position with con-

or get under an engine while it is being

siderable force. If a person is unaware of

supported by hoists. When lowering or

this feature when disengaging the tow bar

raising an engine, do it slowly. Constantly

from a tractor, there is the possibility of

check the engine clearance with the aircraft

personnel injury.

nacelle and controls to prevent damage or

binding.

The 33-gallon solution tank is separated into

two separate compartments. The forward section

is a 7-gallon preservative tank. The rear section

Jet Engine Corrosion

is a 26-gallon freshwater tank. Each tank has its

Control Cart

own filler neck and cap. There is a 4-inch opening

for water and a 2-inch opening for the preservative

The corrosion control cart provides freshwater

tank. Each tank has a pipe plug at the bottom

rinsing or the application of preservation com-

for draining. The freshwater and preservative

pound to the compressor section of an engine

fluid systems each have a shutoff valve, a quick

through a low-pressure spray. See figure 3-22.

Figure 3-21.-Aero bomb hoist.

3-18