Propeller Removal

It usually takes a crew of three to remove the

propeller and place it on the dolly. Refer to the

applicable maintenance instructions for a list of

tools and procedures used to remove the propeller

assembly. Cycle the propeller to maximum reverse

to aid in the removal of the afterbody assembly.

Maximum reverse is the only position that allows

afterbody removal without causing damage to the

afterbody or propeller blades. After you remove

the top and bottom sections, cycle the propeller

back to the feather position. Secure all electrical

power to the propeller. Disconnect the cannon

plugs and propeller control input linkage, and

stow them away to prevent snagging during

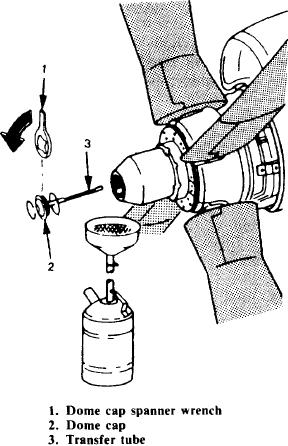

removal. Remove the propeller spinner. Remove

the dome cap and oil transfer tube. Position an

oil shield under the dome to catch oil spillage. See

figure 8-18.

CAUTION

The propeller should NOT be cycled for

at least 10 minutes before removing the

Figure 8-18.-Dome cap removal.

dome cap.

Unscrew the dome retaining nut and remove

Propeller Cleaning

the dome assembly. Remove the pitchlock

assembly with the puller. This assembly includes

If you disassemble the propeller, clean all the

the pitchlock control cam, pitchlock stationary

parts with approved cleaning solution except the

ring and pin, and externally splined spacer ring.

deicing brushes and slip rings. Thoroughly dry all

Install a dynamometer between the hoist and yoke

parts after cleaning. Vapor blasting is NOT

assembly.

permitted on this propeller. The use of rags or

paper for cleaning or wiping internal parts of the

NOTE: When removing or installing

propeller and control assembly is NOT permitted.

the propeller, do not turn the No. 1

The use of these materials may cause lint or

blade beyond positive 100 degrees or

minute particles to enter the hydraulic system.

minus 15 degrees. Movement passed these

Malfunctioning of parts is possible. Unused parts

limits will damage the propeller. Damage

or parts not reassembled within a reasonable time

occurs when the beta follow-up shaft

should be preserved with a corrosion-preventive

releases from the beta gear segment.

compound. Exact procedures for the cleaning and

Damage also occurs when the beta shaft

prevention of corrosion on propellers are found

moves into the control assembly beyond its

in the applicable maintenance instructions.

stops.

Propeller Installation

Remove the propeller and control assembly

Installation procedures are the reverse of

from the propeller shaft. Install them on a dolly,

removal. Before installing the propeller on the

and secure them before removing the hoist.

propeller shaft, install (or clean and inspect) the

Remove the rear cone from the engine shaft

torque retainer (drive bracket assembly) and the

and retain it with the propeller assembly. See

negative torque bracket assembly on the engine

figures 8-19 and 8-20.

8-20