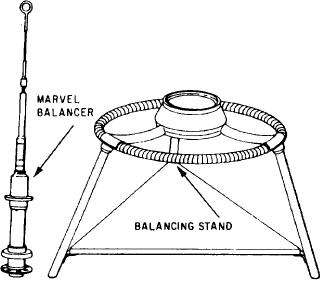

kit 7A100, or its equivalent. See figure 8-22.

its cotter pin) in place at its normal locking

Before performing actual propeller assembly

position.

buildup and balancing, you must always refer to

Final Balance Check

the appropriate technical publication.

Preliminary and final balance has already been

completed on new and overhauled propellers

The final balance check is obtained by adding

before they are disassembled and shipped to an

bolts, washers, and nuts to balancing holes in the

AIMD. Do not perform preliminary balance if

deicer contact ring holder assembly near the outer

edge. If possible, bolts, washers, and nuts should

final balance can be obtained first.

be divided equally on each side of the deicer

NOTE: The final balance check can be

contact ring holder assembly. Do not disturb

erroneous because of residual hydraulic

similar bolts, washers, and nuts, which are painted

red and already located in the balancing holes.

fluid in the propeller dome assembly. You

must make sure the dome assembly is com-

They are used for balance of the holder assembly

pletely drained of any residual hydraulic

itself, not the propeller. Use special bolts, washers,

fluid before installing the dome assembly

and nuts on the deicer contact ring holder

for the final balance cheek.

assembly installed on the propeller. For the

plastic molded holder assembly, use no more

You must obtain horizontal balancing on all

than six AN960-10 washers on one bolt; use no

more than six NAS514P1032-16 bolts and six

propellers during assembly. Horizontal balancing

must be performed in a room free of air currents

MS20364-1032A nuts.

and with the propeller assembly clean and dry.

Obtain final balance with the propeller

The plane of the blades must be horizontal, and

assembly mounted on the horizontal balance

machine, with the plane of the blades horizontal

the blade pitch must be set at 45 degrees.

Do not install the dome cap, low pitch stop

and the dome assembly installed. The sensitivity

of the balance machine must be calibrated so that

assembly, pitchlock regulator assembly, propeller

hub nut, hub mounting bulkhead assembly, and

any unbalance shown by the machine may be

corrected or reversed by applying a restraining

their associated parts. These units are not included

moment of 6 inch-ounces.

as part of the balancing procedure. Install the

If final balance cannot be obtained because

dome assembly without the dome-to-barrel

preformed packing and gear preload shims.

of the maximum limit on the number of bolts,

washers, and nuts that can be added to the deicer

Tighten the dome retaining nut snugly past its

normal locking position. Use masking tape to hold

contact ring holder assembly, it is necessary to

obtain preliminary balance first, and then final

the dome retaining nut special head screw (without

balance. Remove the final balance bolts, washers,

and nuts from the holder assembly, if they are

installed.

CAUTION

The bolts, washers, and nuts that are

colored red must not be removed. These

are used for balance of the holder assembly

itself, not the propeller.

Preliminary Balance

If final balance cannot be obtained, pre-

liminary balance must be obtained by installing

balance washers on the blade balancing plugs of

the light blades.

With the propeller suspended on the balancing

stand, you should place the balance washers on

the shanks of the light blades next to the outboard

Figure 8-22.-Propeller balancing kit (7A100).

8-24