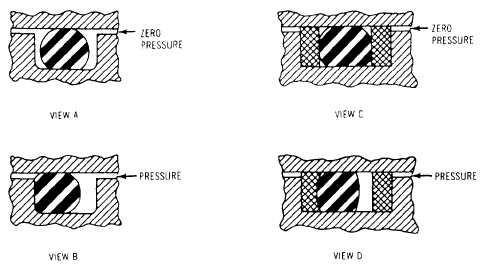

Figure 2-42.—Hydraulic seals.

trimmed to extremely close tolerances. In some

landing gear struts, an elliptical seal is used. The

elliptical seal is similar to the O-ring seal except for

its cross-sectional shape. As its name implies, its

cross section is elliptical in shape. Both the O-ring

and elliptical seals are shown in figure 2-42.

Advances in aircraft design have made new

O-ring composition necessary to meet changing

conditions.

Hydraulic O-rings were originally

established under AN (Air Force-Navy) specification

numbers (6227, 6230, and 6290) for use in fluid at

operating temperatures ranging from -65°F to +160°F.

When new designs raised operating temperatures to a

possible +275°F, more compounds were developed

and perfected.

Recently, newer compounds were developed

under MS (Military Standard) specifications that

offered improved low-temperature performance

without sacrificing high-temperature performance.

These superior materials were adopted in the

MS28775 O-ring, which is replacing AN6227 and

AN6230 O-rings, and the MS28778 O-ring, which is

replacing the AN6290 O-ring. These O-rings are now

standard for systems where the operating

temperatures may vary from -65°F to +275°F.

Packings used in naval aircraft hydraulic

installations are manufactured from synthetic rubber.

They are used in units that contain moving parts, such

as actuating cylinders, selector valves, etc. Although

packings are made in many forms, the O-ring type is

most widely used. The U-rings, V-rings, and other

various types are obsolete in most cases and are not

discussed in this training manual.

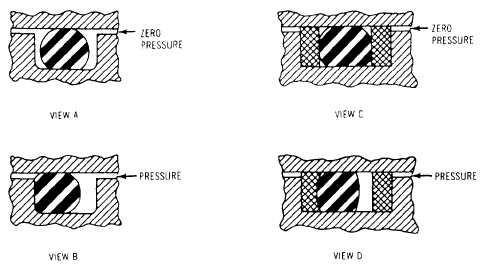

The O-ring packing seals effectively in both

directions. This sealing is done by distortion of its

elastic compound.

Views A and C of figure 2-43

show O-rings of the proper size and installed in

grooved seats.

Notice that the clearance for the

O-rings is less than their free outer diameter. The

cross sections of the O-rings are squeezed out of

round prior to the application of pressure. In this

manner, contact is ensured with the inner and outer

walls of the passage under static (no pressure)

conditions. Views B and D of figure 2-43 show the

action of the O-rings when pressure is applied. You

should also observe, in views C and D of figure 2-43,

that backup rings are installed. In hydraulic systems

of 1,500 psi pressure or less, AN6227B, AN6230B,

and MS28775 packings are used. In such installa-

tions, backup rings are not required, although they are

desirable. In most modern aircraft with hydraulic

system pressures up to 3,000 psi, backup rings are

used in conjunction with the MS28775 packings.

Gaskets are used in the sealing of boss fittings,

end caps of actuators, piston accumulators, and other

Figure 2-43.—Action of O-rings.

2-31