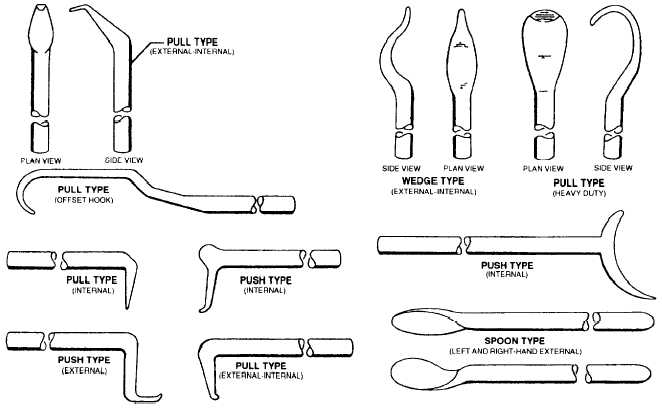

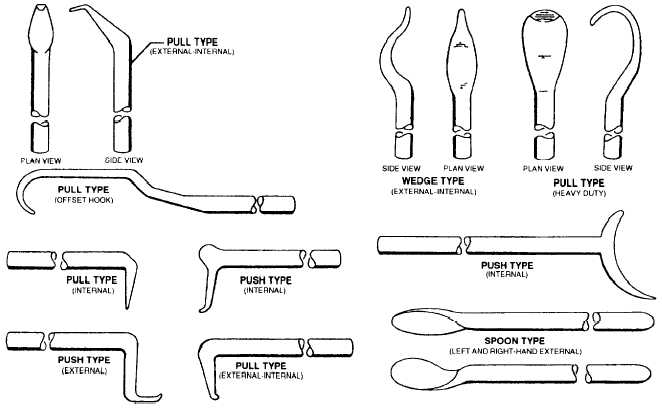

Figure 2-45.—Typical O-ring installation and removal tools.

thinners, moisture, strong drafts, or ozone (form of

oxygen formed from an electrical discharge).

Damage by exposure is magnified when rubber is

under tension, compression, or stress.

There are several conditions to be avoided, which

include the following:

. Deformation as a result of improper stacking of

parts and storage containers

. Creasing caused by a force applied to corners

and edges, and by squeezing between boxes and

storage containers

. Compression and flattening, as a result of

storage under heavy parts

. Punctures caused by staples used to attach

identification

. Deformation and contamination due to hanging

the O-rings from nails or pegs

O-rings should be kept in their original envelopes,

which provide preservation, protection, identification,

and cure date. Contamination is caused by piercing

the sealed envelopes to store O-rings on rods, nails, or

wire hanging devices. Contamination may be caused

by fluids leaking from parts stored above and adjacent

to O-ring surfaces. Contamination can also be caused

by adhesive tapes applied directly to O-ring surfaces.

A torn O-ring package should be secured with a

pressure-sensitive, moistureproof tape, but the tape

must not contact the O-ring surfaces. O-rings should

be arranged so the older seals are used first.

Removal and Installation

The successful operation of a hydraulic system and

the units within depends greatly upon the methods and

procedures used in handling and installing hydraulic

seals. These seals are comparatively soft and should not

be subjected to any nicks, scratches, or dents. They

should be kept free of dirt and foreign matter and should

not be exposed to extreme weather conditions. When

hydraulic seals are chosen for installation, they should

not be picked up with sharp instruments, and the

preservative should not be removed until they are ready

for installation.

During the installation or removal of hydraulic

seals, as well as other tasks, your best friend is the

correct tool. A variety of these tools may be used on

any given job.

Suggestions for fabricating typical

tools for use in replacing and installing O-rings and

backup rings are shown in figure 2-45. These tools

should be fabricated from soft metal such as brass and

2-33