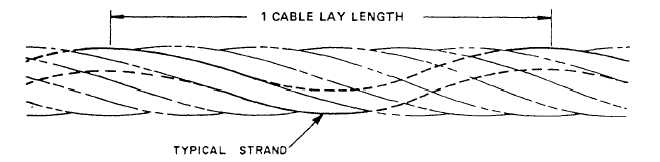

Figure 3-25.—Cable lay length.

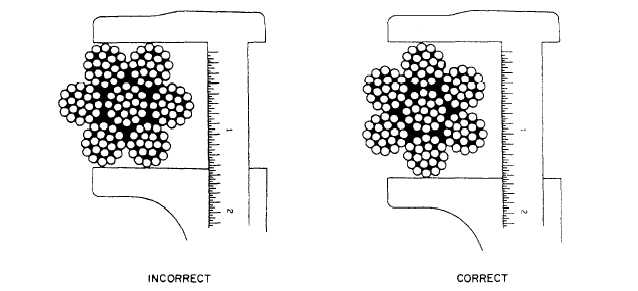

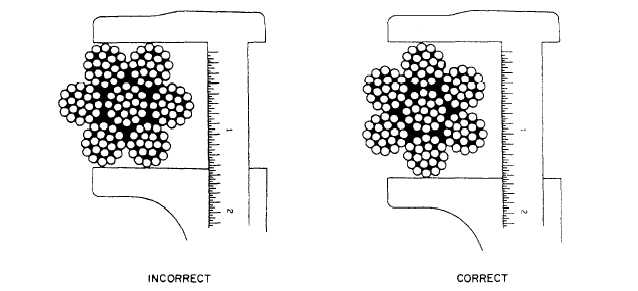

cross section. Figure 3-24 shows the proper method of

measuring the diameter of a wire rope.

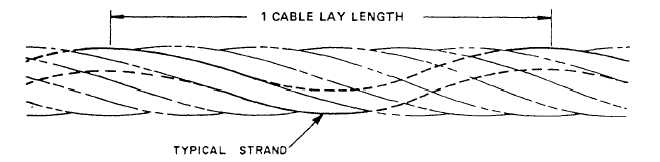

2. Lay Length. The distance, parallel to the axis of

the cable, in which a strand makes one complete turn

about that axis is known as the lay length or pitch length.

Figure 3-25 shows the lay length of a wire rope.

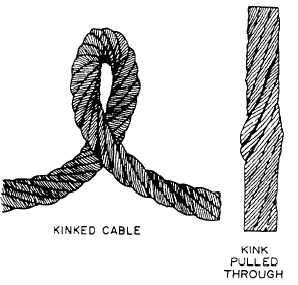

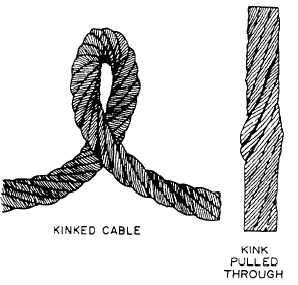

Wire rope cables are visually inspected for knots,

fraying, stretching, abrasions, severe corrosion, and

other signs of failure. Of particular importance is the

detection of a cable in which a kink has been pulled

through in order to straighten the cable. The resultant

deformation is known as a bird cage. See figure 3-26. In

such a case, the sling should be discarded.

The presence of one or more broken wires in one

rope lay length or one or more broken wires near an

attached fitting is cause for replacement. If a broken wire

is the result of corrosion or if the cable is excessively

Figure 3-26.—Cable damage resulting from a pulled-through

corroded, the cable must not be used regardless of the

kink.

3-36

Figure 3-24.—Measuring the diameter of a wire rope.