After the test is complete, the stand is stopped by

slowly opening the outlet valve and decreasing the

pressure with the pressure regulator. When the fluid

pressure gauge reads zero, the Plexiglas cover may be

raised, and the test hose is disconnected and removed.

AIRCRAFT HYDRAULIC HOSE BURST

TEST STAND (CGS SCIENTIFIC CORP)

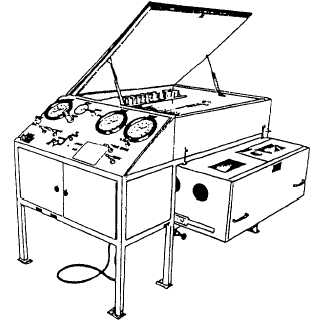

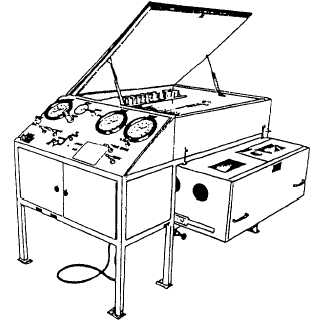

The hose burst test stand, shown in figure 5-18, is

manufactured by CGS Scientific Corporation. This

test stand provides a means for pressure testing of

aircraft hose assemblies of various lengths and sizes.

Hydraulic pressure up to 15,000 psi and pneumatic

pressure up to 1,500 psi are available for the testing of

the hoses.

The test stand is a completely

self-contained unit mounted on legs that permits

bolting to the deck.

Access doors and removable

panels provide easy access to all components for

maintenance.

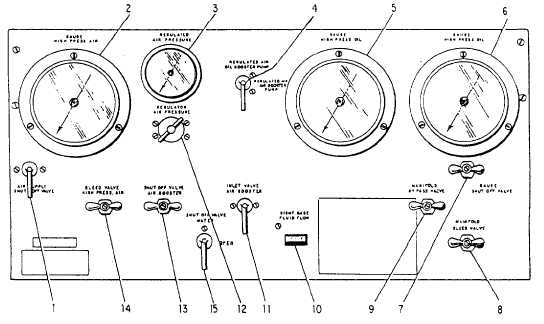

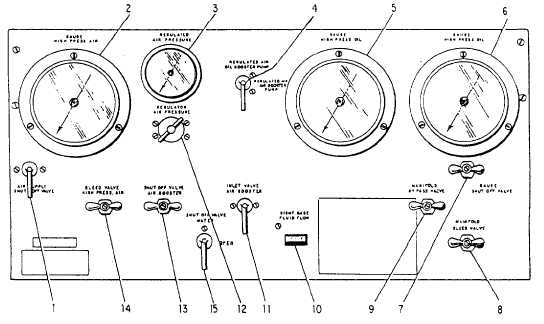

Figure 5-19 shows the controls and

instruments, and table 5-7 lists the functions of each.

Figure 5-18.—Aircraft hose burst test stand (CGS Scientific).

You should be familiar with these controls and

1. AIR SUPPLY SHUTOFF VALVE.

5. HIGH-PRESSURE OIL GAUGE

12. AIR PRESSURE REGULATOR.

2. HIGH-PRESSURE AIR GAUGE

(0-20,000 psi).

13. AIR BOOSTER SHUTOFF

3.

4.

(0-2,000 psi).

6. HIGH PRESSURE OIL GAUGE

VALVE.

REGULATED AIR PRESSURE

(0-2,000 psi).

14. HIGH-PRESSURE AIR BLEED

GAUGE (0-160 psi).

7. GAUGE SHUTOFF VALVE.

VALVE.

SELECTOR VALVE,

8. MANIFOLD BLEED VALVE.

15. WATER SHUTOFF VALVE

REGULATED AIR TO OIL

9. MANIFOLD BYPASS VALVE.

BOOSTER PUMP OR AIR

10. SIGHT GAUGE.

BOOSTYER PUMP.

11. AIR BOOSTER INLET VALVE.

Figure 5-19.—Controls and instruments.

5-20