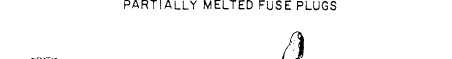

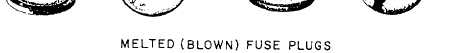

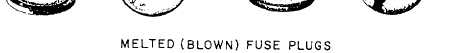

Figure 11-7.—Fuse plugs.

physical damage, and melted fusible plugs. See

figure 11-7. Forward all wheels with cracks or loose

bearing cups to supply for overhaul. Partially melted

fuse plugs should not cause a wheel to be rejected.

The plug may not need to be replaced. If the eutectic

core material does not extend more than one-sixteenth

of an inch above the top surface of the hex head, the

plug may be kept in service “as is” with no

restrictions.

If the eutectic core material at the

threaded end is not depressed more than one-sixteenth

of an inch and there is no evidence of pinholes, the

plug may be kept in service with no restrictions. Do

not file, sand, or remove the eutectic material. If the

eutectic material appears to be filed, sanded, or

broken, you should assume the serviceable limits

have been exceeded and reject the plug.

You should perform the eddy current and dye

penetrant inspections for wheels listed in NAVAIR

04-10-1.

Inspect all tie bolts for corrosion,

elongation, bending, stripped threads, or deformed

shanks. You should also perform a magnetic particle

inspection for cracks according to NAVAIR

01-1A-16. Any of the listed defects is cause for

rejection of the tic bolt. Self-locking tie bolt nuts may

be reused provided the nut cannot be turned onto the

tie bolt by hand with the fingertight method

prescribed in Structural Hardware, NAVAIR

01-1A-8. On disc wheels, you should inspect brake

keys or gears for wear and looseness in accordance

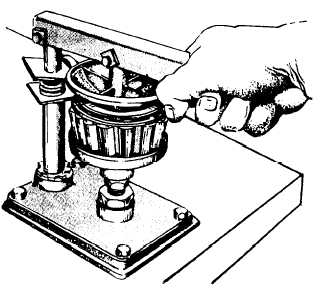

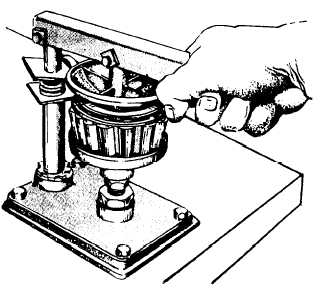

Figure 11-8.—Pressure repacking of wheel bearings.

11-8