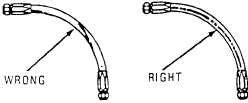

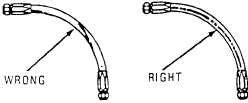

Figure 5-20.—Hose twist.

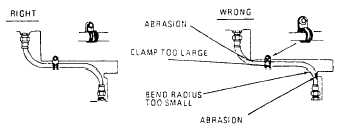

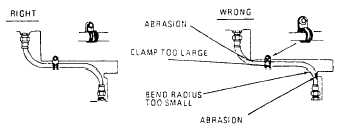

Figure 5-22.—Hose clamp mounting.

inspection light into one end and visually inspect from

the opposite end using a small, angled, dental-type

mirror. Inspect for any separation of covers or braids

from inner tube, or from adjacent covers or braids.

Look for flaring or fraying of braid. Look for blisters,

bubbles, or bulging. Inspect for corrosion. A hose

that has carbon steel wire braid is subject to corrosion,

which may be detected as brownish rust coloration

penetrating the outer braid.

Inspect end fittings for proper type and size,

corrosion and cleanliness, nicks, scratches, or other

damage to the finish that affects corrosion resistance.

Look for damage to threaded areas, damage to

cone-seat sealing surfaces damage to flange fittings,

warping of flange, and for nicks or scratches on the

sealing surface or gasket.

Installation Procedures

Remove the protective closures from hydraulic

lines, hose, or hose assemblies. When possible,

install hose or hose assemblies so that identification

markings are visible. Install hose or hose assemblies

without twisting, chafing, or overbending (fig. 5-20).

Observe bend radius in table 5-8. Greater

bend-radius is preferred where possible. Install hose

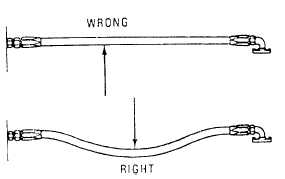

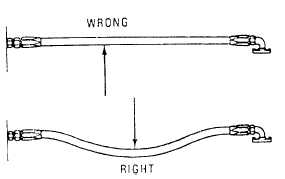

or hose assemblies with a slight bow or slack to

compensate for contraction pressure on the line

(fig. 5-21).

Figure 5-21.—Hose slack.

When connecting hose or hose assemblies to an

engine or an engine-mounted accessory, provide 1 1/2

inches of slack or a suitable bend between the last

point of support and the engine or accessory

attachment. Fingertighten swivel connector nuts to

avoid stripping threaded areas of fittings. Before

applying final torque to end fittings, make sure hose

Table 5-9.—Swivel Nut Installation Torque (Inch-Pound) for

Flared and Flareless Fittings

HOSE

STEEL

ALUMINUM

SIZE

MIN

MAX

MIN

MAX

2

75

85

20

30

3

95

105

25

35

4

135

145

50

65

5

170

190

70

90

6

215

245

110

130

8

430

470

230

260

10

620

680

330

360

12

855

945

460

500

16

1140

1260

640

700

20

1520

1680

800

900

24

1900

2100

800

900

32

2660

2940

1800

2000

NOTE:

Torque values based on lubrication

with fluid MIL-H-5606 or

MIL-H-83282 prior to installation.

5-26