Skin Fasteners

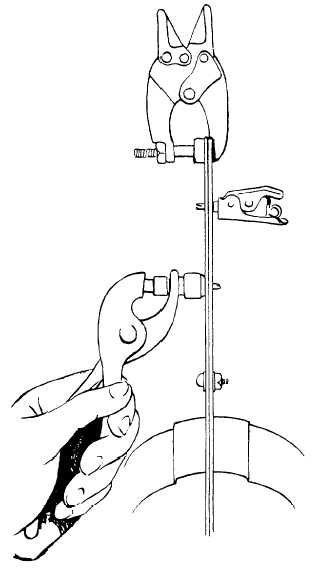

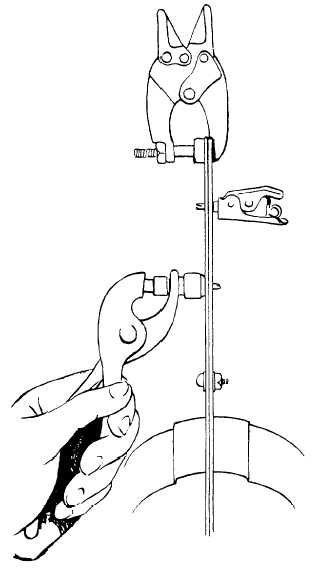

There are several types of skin fasteners used to

temporarily secure parts in position for drilling and

riveting and to prevent slipping and creeping of the

parts. C-clamps, machine screws, and Cleco

fasteners are frequently used for this purpose. See

figure 13-6. Cleco fasteners come in sizes ranging

from 1/1 6 to 3/8 of an inch. The size is normally

stamped on the fastener, but may also be recognized

by the following color code:

1/16 inch—black

3/32 inch-cadmium

1/8 inch-copper

5/32 inch—black

3/16 inch—brass

1/4 inch—green

3/8 inch—red

The Cleco fastener is installed by compressing the

spring with Cleco pliers (forceps). With the spring

compressed, the pin of the Cleco is inserted in the

drilled hole. The compressed spring is then released,

allowing spring tension on the pin of the Cleco to

draw the materials together. Clecos should be stored

on a U-channel plate to protect the pins of the Cleco.

Storing Clecos at random among heavy tools will

result in bent pins.

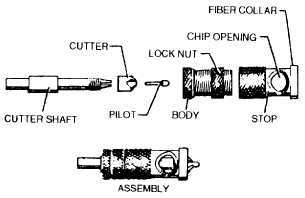

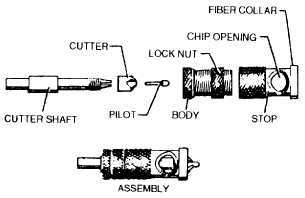

Machine Countersink

Machine countersinking is used to flush rivet

sheets 0.064 of an inch and greater in thickness. A

countersink has a cutting face beveled to the angle of

the rivet head, and is kept centered by a pilot shaft

inserted in the rivet hole. When a conventional

countersink is used, you should try each hole with a

rivet or screw to ensure the hole has not been

countersunk too deeply. The adjustable countersink is

the best tool to use because the depth of the hole can

be controlled. A stopping device automatically acts as

a depth gauge so that the hole will not be countersunk

too deep. Figure 13-7 shows an adjustable stop

countersink.

The countersink should always be equipped with

a fiber collar to prevent marring of the metal surface.

A drill motor or hand drill (electric or air) maybe used

to operate the countersink. However, it should not be

operated above 2,500 rpm. The countersink must be

sharp to avoid vibration and chatter.

Figure 13-6.—Skin fasteners.

Figure 13-7.—Adjustable stop countersink.

13-4