The flat end of the head is called the face. This

end is used for most hammering jobs. The domed end

of the hammer is called the peen. The peen end is

smaller in diameter than the face, and is useful for

striking in areas that are too small for the face to enter.

Ball peen hammers are made in different weights,

usually 4, 6, 8, and 12 ounces and 1, 1 1/2, and

2 pounds.

For most work, a 1 1/2-pound and a

12-ounce hammer will suffice.

MALLETS.—A mallet is a soft-faced hammer.

Mallets are constructed with heads made of brass,

lead, tightly rolled strips of rawhide, plastic, or plastic

with a lead core for added weight.

A plastic mallet, similar to the one shown in

figure 13-1, is the type normally found in the AM’s

toolbox. The weight of the plastic head may range

from a few ounces to a few pounds; however, the size

of the plastic mallet is measured across the diameter

of the face.

The plastic mallet may be used for

straightening thin sheet ducting or for installing

clamps.

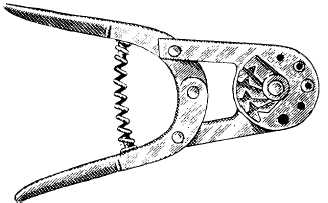

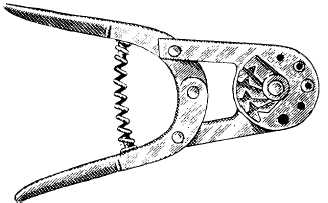

Rotary Rivet Cutters

In case you cannot obtain rivets of the required

length, rotary rivet cutters may be used to cut longer

rivets to the desired length. See figure 13-2. When

you use the rotary rivet cutter, insert the rivet part way

into the correct diameter hole.

Place the required

number of shims (shown as staggered, notched strips

in the illustration) under the head and squeeze the

handles. The compound action from the handles

rotates the two discs in opposite directions. The

rotation of the discs shears the rivet smoothly to give

the correct length (as determined by the number of

Figure 13-2.—Rotary rivet cutter.

shims inserted under the head). When you are using

the larger cutter holes, place one of the tool handles in

a vise, insert the rivet in the hole, and shear it by

pulling the free handle. If this tool is not available,

diagonal-cutting pliers can be used as an emergency

cutter, although the sheared edges will not be as

smooth and even as when they are cut with the rotary

rivet cutter.

Rivet Set

A rivet set is a tool equipped with a die for driving

a particular type of rivet. Rivet sets are used in both

hand and pneumatic hammer riveting methods. Rivet

sets are available to fit every size and shape of rivet

head. The ordinary hand set is made of 1/2-inch

diameter carbon steel about 6 inches long. It is

knurled to prevent slipping in the hand. Only the face

of the set is hardened and polished. Sets for the

oval-head rivets (universal, round, and brazier) are

recessed (or cupped) to fit the rivet head. When you

select a rivet set, be sure that it will provide the proper

clearance between the set and the sides of the rivet

head and between the surfaces of the metal and the

set. Flush or flat sets are used for countersunk and

flat-head rivets. To set flush rivets properly, the flush

sets should be at least 1 inch in diameter.

Special sets, called “draw” sets, are used to “draw

up" the sheets being riveted in order to eliminate any

opening between them before the rivet is bucked.

Each draw set has a hole 1/32 of an inch larger than

the diameter of the rivet shank for which it was made.

Sometimes, especially in hand-working tools, the

draw set and the rivet header are incorporated into one

tool. The header consists of a hole sufficiently

shallow for the set to expand the driven rivet

“bucktail” and form a head on it when the set is

struck by a hammer.

Figure 13-3 shows a

rectangular-shaped hand set that combines the draw

and header sets and a flush set used with a pneumatic

hammer.

Sets used with pneumatic hammers (rivet guns)

are provided in many sizes and shapes to fit the type

and location of the rivet. These sets are the same as

the hand rivet sets except that the shank is shaped to

fit into the rivet gun. The sets are made of high-grade

carbon tool steel and are heat-treated to provide the

necessary strength and wear resistance. The tip or

head of the rivet set should be kept smooth and highly

polished to prevent marring of rivet heads.

13-2