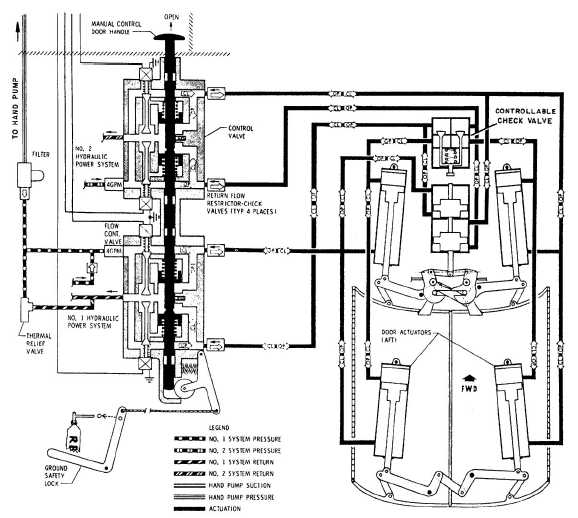

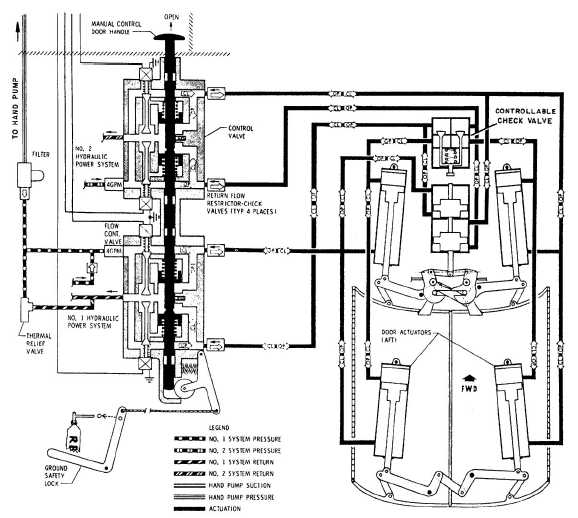

Figure 12-67.–Bomb bay door hydraulic schematic.

bypassing more or less of the airflow at the engine face,

as shown in figure 12-66.

The system adjusts the bypass bellmouth ring

position to maintain a preselected inlet airspeed and

stable mass airflow through the inlet duct throughout

the flight range of the aircraft. Movement of the

bellmouth ring also controls the amount of secondary

air bypassed around the engine for cooling. The valves

in the bellmouth controller (fig. 12-66) are positioned

by the inlet duct pressure differential and, in turn,

direct hydraulic pressure to the bellmouth ring

actuator, increasing or decreasing the bypass opening.

The holes drilled in the bypass ring assure cooling air

to the engine compartment when the ring is in the

closed position.

Auxiliary air doors (not shown in fig. 12-66) open to

supplement the bellmouth bypass system at low

airspeeds and during ground operation to prevent

overtemperature and/or reverse airflow in the engine

compartment. These doors are located on the underside

of the fuselage and open in flight, at high speeds, as

required to prevent excessive air pressure differential

between the engine compartment and outside ambient.

The auxiliary doors are held closed by hydraulic

actuators, which are sized to develop a force equivalent

to the door area times the designated differential

pressure. When the pressure limit is exceeded, the door

is pushed open (varying amounts) to keep the engine

compartment pressure from becoming excessive. As the

engine compartment pressure is lowered, the hydraulic

actuators will pull the doors closed.

The variable ramp, bellmouth bypass, and auxiliary

air door systems are powered by the utility hydraulic

system. Malfunctions in these systems will normally

require personnel of the AE, AD, and AM ratings

working together to operationally test the system and

provide proper corrective maintenance.

BOMB BAY SYSTEM

The bomb bay system is shown in figure 12-67. The

doors are actuated by mechanical linkage at each end.

12-77