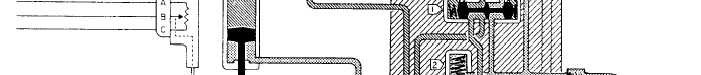

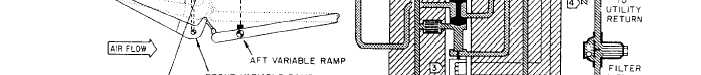

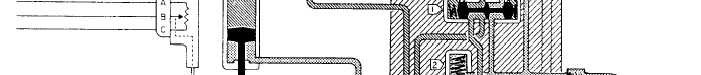

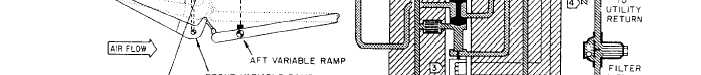

Figure 12-65.–-Ramp servo and actuator.

given to cautions and warnings and specified quality

assurance considerations.

VARIABLE RAMP AND

BELLMOUTH SYSTEMS

The airflow velocities encountered in the higher

speed ranges of aircraft are much higher than the engine

can efficiently use. Therefore, the air velocity must be

controlled for acceptable engine performance.

The variable inlet ramp system positions the inlet

ramp (located in the air inlet) so that it will position the

shock wave to decrease the inlet air velocity to a

subsonic flow with a maximum pressure energy. The

system also provides for the reflection and bypass of

surplus air not required by the engine with a minimum

of drag. The inlet system in combination with the bypass

bellmouth system allows the inlet duct to take aboard

the maximum free airstream. The air not required by the

engine is bypassed by the action of the bellmouth ring.

Figure 12-65 shows the ramp sections and

associated hydraulic mechanism and linkage. The aft

ramp is positioned by the hydraulic actuator. The

actuator is controlled by the electrically operated torque

motor in the hydraulic servo valve.

Movement of the aft ramp positions the perforated

ramp through mechanical linkage. The position of

ramps is automatically selected through the ramp

system by a temperature signal from the air data

computer set. The ramp actuator is a double-acting

cylinder attached to the ramp linkage in such a way as

to be free floating. This arrangement causes equal action

on the linkages attached to each end of the cylinder.

Figure 12-65 shows the complete hydraulic portion

of the variable ramp system, showing the actuator

extending. Actuating the torque motor armature

positions the flapper valve in the servo valve, initiating

the proper servo action to extend, retract, or hold the

actuator in position. As the actuator moves, it positions

the ramp through its mechanical linkage.

Electrical components in the circuit translate an

electrical signal, proportional to the ramp movement, to

balance the amplifier circuits and hold the servo and

ramp at this designated position until a new temperature

signal initiates a change. If electrical or hydraulic power

failure occurs, air loads on the ramps will tend to cause

the ramps to move toward the retract position.

The variable bypass bellmouth system monitors the

inlet duct operation and indicates any corrective action,

12-75