controlled by three switches on the bleed-air

section of the ice protection panel. When the

solenoid is energized, it admits filtered, regulated,

bleed-air pressure to one side of a diaphragm

chamber in the valve. The other side of the

diaphragm chamber is spring-loaded to the closed

position. Movement of the diaphragm operates

a main line butterfly valve.

When the valve opens, hot air is admitted to

the leading edge distribution system. The hot air

goes through the modulator valve to the ejector

manifold, out the jet nozzles, and into the wing

leading edge plenum area. The bleed air is then

directed across a pneumatic thermostat. Increased

temperature across the thermostat actuates the

sensor and opens a bleed passage from the

diaphragm chamber. This reduces the pressure on

the diaphragm and allows a spring to close the

main valve.

THERMOSTATS.— The wing leading edge

pneumatic thermostat is installed adjacent to each

modulating valve. (See fig. 3-2.) The thermostat

controls air pressure on the modulating valve

diaphragm, and thereby controls the valve

opening.

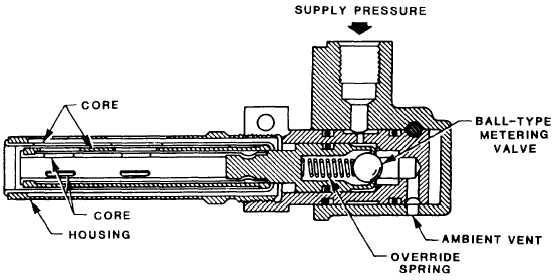

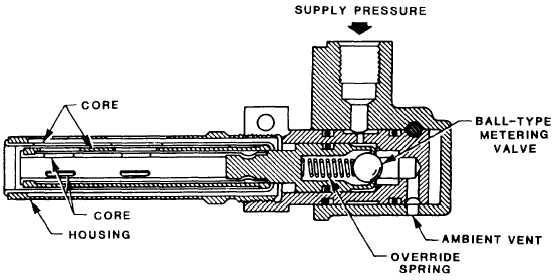

The unit is composed of a probe and a valve

assembly. (See fig. 3-3.) The probe is a core made

of layers of high- and low-expansion material that

is locked to a sliding piston. In addition, the piston

contains an override spring and ball-type metering

valve.

Airflow from the leading edge flows over the

core and causes the materials to expand or

contract. As temperature rises, the core pulls the

piston and metering ball from the seated position.

This allows pressure from the modulating valve

diaphragm to vent. Increasing temperature causes

more air to be bled from the diaphragm chamber.

Because of spring action, the modulating valve

moves toward the closed position. This restricts

flow through the modulator valve and drops the

skin temperature.

LEADING EDGE TEMPERATURE AND

OVERHEAT CIRCUIT.— To monitor the

overheat warning system, six skin temperature

sensors (one in the inboard section, one in the

center section, and one in the outboard section

of each wing) form a part of an amplifier circuit.

When the wing leading edge skin temperature rises

in excess of 230°F at any one or more sensors,

the airfoil temperature control unit amplifier

completes a caution light circuit, thus illuminating

the leading edge caution hot light.

Also, there are three ducting overheat thermal

switches installed in each wing and three installed

in the fuselage adjacent to the bleed-air duct.

These switches form a part of a loop that is

connected to a signal light control assembly.

When any one of the thermal leak detector

switches closes, its respective caution light

illuminates. Also, when the test switch is placed

in the TEST position, both lights illuminate

through their respective loop circuit.

The ducting overheat switches are single-pole,

single-throw, explosiveproof, thermally actuated

electrical switches with an integral temperature

Figure 3-3.-Wing leading edge thermostat.

3-4