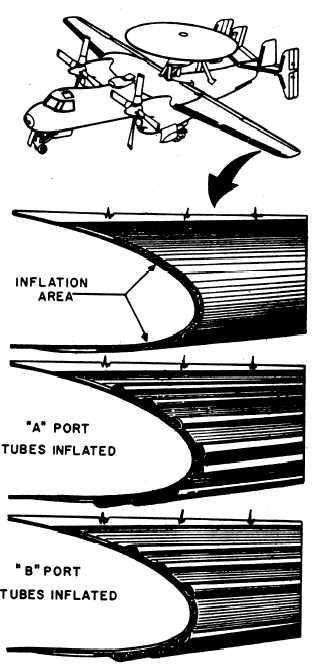

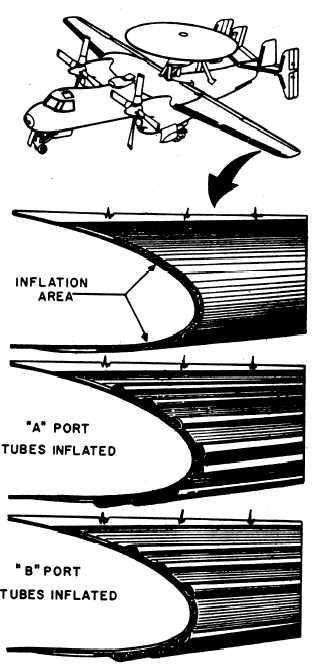

or tubes of the deice boots (fig. 1-7) are inflated

and deflated alternately by applying pressure and

suction, causing a wavelike motion that cracks the

formed ice and allows it to be carried away by

the airstream.

The E-2A deice boot system shown in

figure 1-8 is pneumatically operated and

electrically controlled. Engine bleed air provides

the necessary air pressure. The bleed air is

regulated by the pressure regulator and relief

valve. Suction is provided by the ejector and

regulated by the suction relief valve. Suction and

pressure gages provide a means of monitoring

system readings that indicate proper or improper

system operation.

The deice system consists of the follow-

ing main components: electronic timer, three

distributor valves, pressure regulator and relief

valve, ejector, suction relief valve, the de-

ice boot sections, and pressure and suction

gages.

ELECTRONIC TIMER.— A timer controls

the inflation and deflation of the deice boots by

alternately energizing and de-energizing the

solenoids of the distributor valves in a specific

sequence. Pressure and suction are applied to the

boots in the following sequence: the inboard wing

boots, the outboard wing boots, the outboard

stabilizer and vertical fin boots, and the inboard

stabilizer and fin boots.

Each group of boots is inflated for approx-

imately 5 seconds, and the succeeding group

begins inflating approximately 10 seconds after

the first group begins deflating. The total time for

the complete inflation cycle to all four boot groups

is approximately 1 minute. The timer is a sealed

unit and is maintained by personnel in the AE

rating.

DISTRIBUTOR VALVES.— Each of the

deice system’s three distributor valves (fig. 1-8)

has a pressure inlet port, a suction inlet port, two

outlet ports to the deice boots, and an exhaust

port. The exhaust port routes air returning to the

distribution valve in the deflation cycle overboard

to a low-pressure area. The low-pressure exhaust

area creates a slight suction to assist in deflation

of the boot. The pressure inlet port is connected

to the engine bleed-air manifold pressure line. The

Figure 1-7.—Deice boot location/operation.

suction port is connected to the main suction

line from the ejector. Approximately 4 in

Hg. suction is available at all times to the

distributor valves. Each distributor valve has

two solenoids that, when energized, allow air

pressure to inflate their respective boot tubes,

as was shown in figure 1-7. When the solenoids

are de-energized, the valves allow suction to

be applied to the boots, holding them down

(deflated) in flight.

1-8