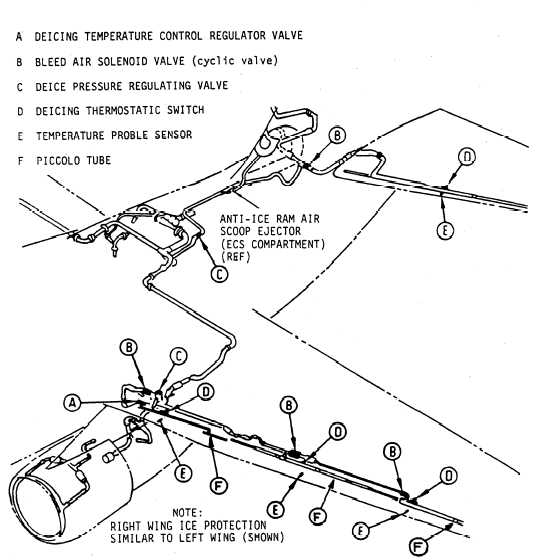

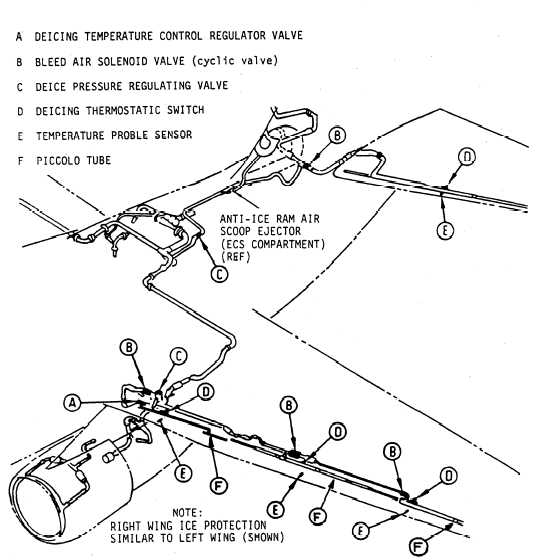

supply subsystem, in addition to supplying deice

air, is to control the temperature of that supply.

The high-stage bleed-air regulator valve primarily

maintains a set pressure schedule in the bleed-air

manifold. During deice operations this function

is expanded to maintain a temperature of

500°±25°F (260°±14°C) (or maximum 14th

stage temperature, if less than 500°F).

Pneumatic signals from the bleed-air control

temperature thermostat and anticipator are fed

to the deice temperature control regulator valve

(fig. 1-10), which, in turn, signals the high-stage

bleed-air regulator valve to open, as necessary,

to satisfy either the pressure schedule or the 500°F

requirement, whichever needs the larger amount

of 14th stage bleed air. Both engines are connected

by the cross-bleed manifold, which provides a

flow path for bleed air from either one or both

engines. The total deice system is controlled by

the timing control, which uses pressure regulator

valves and cyclic valves to direct bleed air in the

proper sequence to each of the eight deice

segments. Sequencing minimizes bleed-air con-

sumption. Bleed air is ported from the cross-bleed

manifold to each of the pressure regulator valves.

The pressure regulator valves are energized by

setting the DEICING switch on the environmental

panel on the center console to WING EMP (wing

and empennage). Setting this switch energizes a

solenoid that ports pressure from the bleed-air

supply to open the pressure regulator valve. Duct

pressure is regulated by the pressure regulator

valve to 26 ±2 psi. In the de-energized position,

the pressure regulator valves are pneumatically

Figure 1-10.—Ice protection system.

1-12