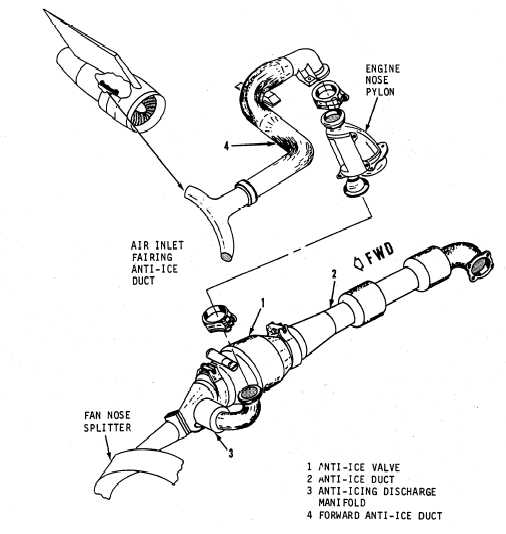

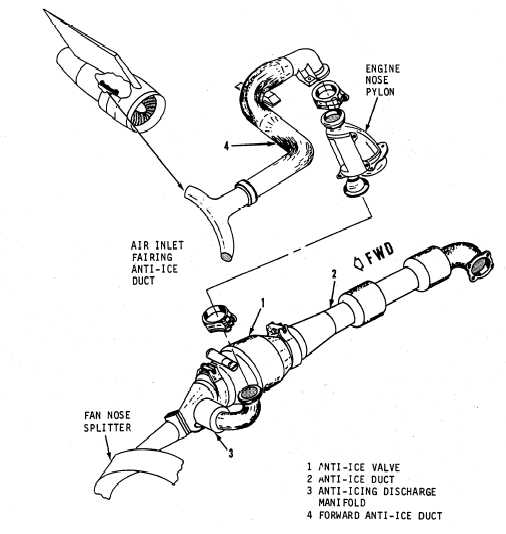

Engine and engine nacelle inlet anti-icing

(fig. 1-11) is accomplished by 14th stage bleed air,

which is separated, in each engine pylon, from

14th stage air being used for other environmental

control system (ECS) purposes. The anti-ice

switch on the environmental panel on the center

console, when set to the ENG & PITOT position,

opens both engine anti-icing valves by de-

energizing their solenoids to direct 14th stage bleed

air, regulated to 22.5 ± 2.5 psi, to the engine

nacelle leading edges and engine anti-icing

systems. The position of each anti-ice valve is

shown on the copilot’s advisory panel; 1 A-ICE

ON and 2 A-ICE ON indicator lights come on

whenever the anti-ice valves are open. The engine

anti-ice switch also opens the empennage pressure

regulator valve to provide a source of constant

bleed air to the ram air inlet duct anti-icing shroud

(unless the deice system is being operated, the

empennage cyclic valves will remain inactive/

closed). The engine anti-icing valve activates the

entire deice system. The deice system cannot be

operated until the anti-ice switch is set to the ENG

& PITOT position.

The bleed-air deice/anti-icing system consists

of deice pressure regulating valves, bleed-air

solenoid valves, a WING & EMP deice timing

controller, a probe sensor temperature trans-

mitter, and a deice thermostatic switch.

Deice Pressure Regulating Valve

The system (fig. 1-12) uses three pressure

regulating valves. One pressure regulating valve

Figure 1-11.—Engine anti-icing system.

1-14