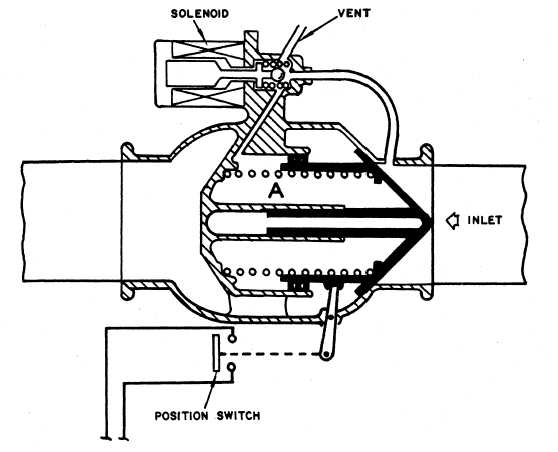

When the solenoid is not energized, chamber

B is vented to ambient pressure and the

valve sleeve remains in the closed position.

To activate the system, the solenoid is en-

ergized, which enables reference control air

pressure to reach chamber B to overcome sleeve

spring force and start to open the valve sleeve.

If the inlet pressure is only ambient pressure, the

sleeve remains fully closed. A 2 psi margin

of inlet pressure over outlet pressure starts the

sleeve opening action. When inlet pressure reaches

30 psi absolute (psia) and outlet pressure is

at the 26±2 psia setpoint, the valve sleeve

opens. Further increase of inlet pressure,

which would otherwise cause an increase

in outlet pressure, is sensed in chamber A,

which adds to the closing force of the valve

sleeve. As the valve sleeve moves toward a

more closed position, the outlet pressure is

reduced and the 26±2 psia setpoint is main-

tained. Continued increase of inlet pressure

results in continued valve sleeve closure until

the pressure regulator valve is completely

closed, thereby preventing outlet pressure from

exceeding 28 psia.

Bleed-Air Solenoid Valve

Eight cyclic valves are used in the deice system.

Two cyclic valves are located in each outboard

wing, one in each inboard wing, and one in each

horizontal stabilizer. The cyclic valve is normally

spring-loaded closed, electrically controlled, and

pneumatically actuated. The cyclic valve controls

the cyclic distribution of bleed air to the

appropriate segment of the deice system piccolo

tubes.

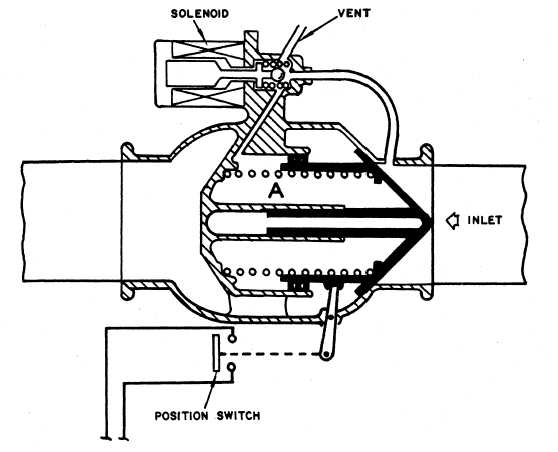

The cyclic valve is pneumatically controlled

by a bleed-air solenoid valve (fig. 1-13). When the

solenoid is not energized, the spring keeps the

cyclic valve closed, and inlet pressure is vented

to ambient and to the closing side of the valve

(chamber A). When the solenoid is energized, the

inlet pressure is blocked, and when it builds to

Figure 1-13.—Bleed-air solenoid valve.

1-16