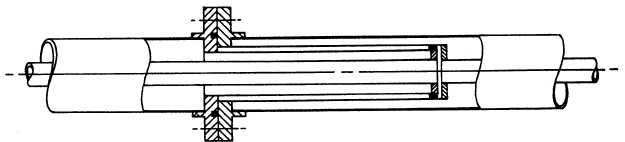

Figure 5-3.—Transfer line connector/coupling.

line. The reason is that as the LOX vaporizes, the

vapors will warm, and excessive pressures may

develop that can burst the conduit walls.

For transfer efficiency, vacuum-jacketed lines

with well-designed, low-heat input couplings are

best for most uses. Unthinking use of two or three

transfer sections coupled together where one could

do the job wastes liquid and time. Several times

as much line material has to be cooled down, and

several times more heat transferring line surface

area is contacted by the LOX. Additional heat

influx means additional LOX vaporization;

therefore, more liquid is needed to satisfy a given

transfer demand.

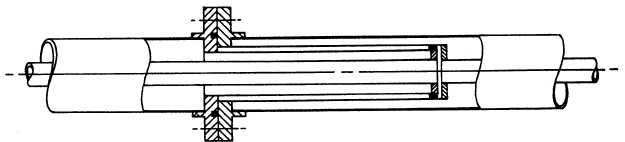

VALVES

Although valves might appear to be of minor

concern in a system, low-temperature valves often

cause more trouble than any other element of the

system. In addition to the general requirements

for any valve, LOX valves must be able to

function properly at extremely low temperatures

without causing excessive boil-off losses to the

liquid flowing through them. Insulation is the best

method to meet these thermal requirements.

Various materials have been used for insulation,

but the best method is to vacuum insulate the

valve. The valve illustrated in figure 5-4 is typical

of this type. The method of operation will vary

by manufacturer.

OXYGEN SERVICING EQUIPMENT

Learning Objective: Describe oxygen

servicing equipment to include safety

precautions, servicing trailers, and system

servicing.

Figure 5-4.—Vacuum-insulated cryogenic valve.

Oxygen servicing equipment for both liquid

and gaseous oxygen systems are discussed in this

5-3