with steel taps or hobnails. Oxygen-permeated

clothing will burn vigorously—a most painful way

to die.

11. When servicing a liquid oxygen system,

ensure that only oxygen conforming to specifica-

tion MIL-0-27210D is used. Oxygen procured

under Federal Specification BB-0-925A is intended

for technical use and should NOT be used in air-

craft oxygen systems.

12. After the completion of repairs, always

perform an operational check of the system and

make the required tests to ensure that the oxygen

is safe for use by the pilot and crew.

ONBOARD OXYGEN

GENERATING SYSTEM

Learning Objective: Identify the system

components and operation of the onboard

oxygen generating system.

The onboard oxygen generating system

(OBOGS) is an alternative to liquid oxygen

(LOX). When compared to a LOX system, the

OBOGS has several advantages. First, its

availability y may be as high as 99 percent. There

is no requirement for depot-level maintenance.

The OBOGS has no daily service requirements,

and scheduled preventive maintenance occurs at

2,000 hours. Incorporation of the OBOGS

eliminates the need to store and transport LOX.

Additionally, it eliminates the need for LOX

support equipment. The potential for accidents

related to LOX and high-pressure gases is greatly

reduced.

SYSTEM COMPONENTS

The basic components of the OBOGS are the

concentrator, oxygen monitor, and oxygen

breathing regulator. The concentrator produces

an oxygen-rich gas by processing engine bleed air

through two sieve beds. The oxygen monitor

senses the partial pressure of the gas and, if

necessary, provides a low-pressure warning to the

pilot. The oxygen regulator is a positive pressure

regulator.

SYSTEM OPERATION

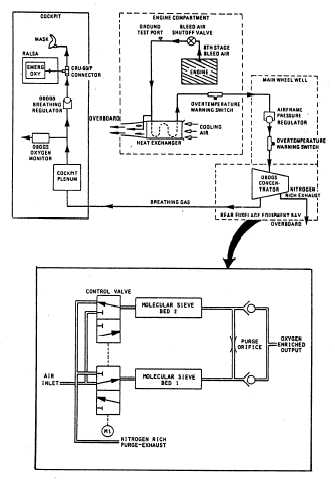

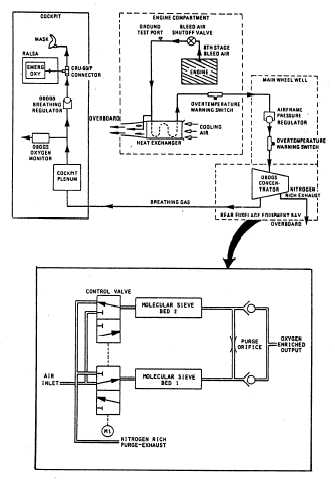

The OBOGS, shown in figure 4-16, receives

engine bleed air from the outlet of the air-

conditioning heat exchanger. The partially cooled

air passes through an air temperature sensor to

a pressure reducer assembly. The air is then routed

Figure 4-16.—Onboard Oxygen Generating System

(OBOGS) schematic.

to the concentrator. The concentrator has a rotary

valve that alternates the airflow over the molecular

sieve beds. The sieve beds absorb the nitrogen and

allow the oxygen and argon to pass through. TWO

molecular sieve beds are used in the concentrator

so that while one bed is absorbing, the other is

desorbing (releasing) nitrogen. This method allows

a continuous flow of oxygen to the system. After

the concentrator, the oxygen flows to a plenum

assembly that acts as a surge tank and an

accumulator. The plenum also functions as

a heat exchanger to heat or cool the oxygen to

approximately cockpit temperature. Before the

oxygen reaches the oxygen regulator, the oxygen

performance monitor senses the partial pressure

of the gas and, if necessary, provides a signal to

the pilot whenever the pressure exceeds prescribed

limits. The oxygen then flows through the

regulator to the pilot’s mask.

4-25