6. SMDC and FCDC assemblies that do not

pass inspection must be replaced. Repair of

SMDC tubing is not permitted.

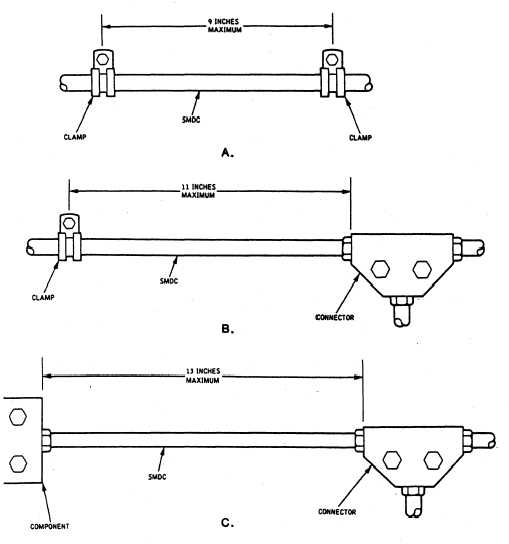

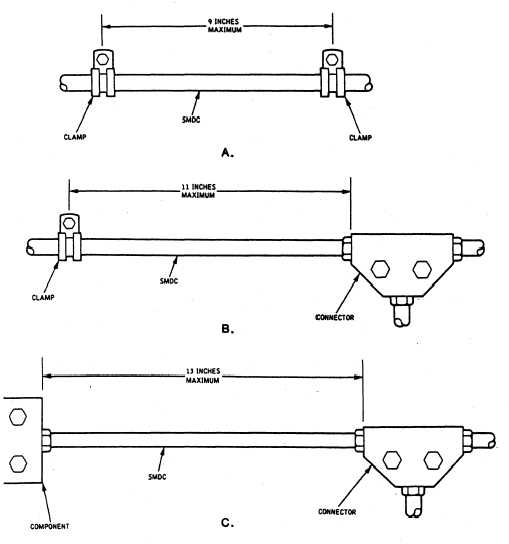

7. Proper clamp spacing (fig. 2-21) must

be maintained to prevent damage to SMDCs

due to vibration. Improper clamp spacing

may result in failure of the SMDC.

SMDC Clearance

Correct clearances must be maintained

between SMDCs, SMDC and adjacent structures,

and tubing and operating mechanisms. In-

sufficient clearances may result in damage to or

failure of the SMDC. You must ensure SMDCs

are installed with proper clearances as listed

below:

1. Minimum required clearance between any

supported section of SMDC and the adjacent

structure is 1.00 inch.

2. Minimum required clearance between any

straight, unsupported section of SMDC and an

adjacent structure is 0.25 inch.

3. Minimum required clearance between any

two parallel SMDCs is 0.10 inch.

4. Minimum required clearance between any

two supported nonparallel SMDCs is 0.10 inch.

5. Minimum required clearance between any

two unsupported nonparallel SMDCs is 0.10 inch.

6. Minimum required clearance between any

supported section of SMDC and any operating

mechanism is 1.00 inch.

Figure 2-21.—SMDC clamp spacing.

2-28