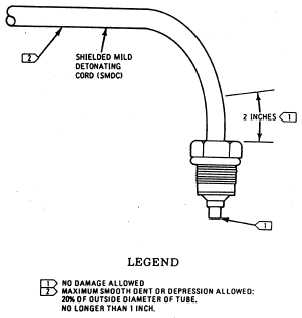

Figure 2-19.—Standard SMDC/FCDC tip assembly.

To properly inspect SMDCs and FCDCs, you

should adhere to the following requirements and

precautions:

1. Ensure ground safety devices required

during maintenance are correctly installed.

2. To prevent damage to the SMDC and

FCDC booster tips, you should use extreme

caution during removal and installation. All open

connections must be capped with protective covers

to prevent damage to SMDC and FCDC booster

tips and contamination of open fittings.

3. Inspect each SMDC and FCDC assembly

fitting nut for deformation, flattening, or wrench

cutting.

4. There must be no corrosion, cracks,

discoloration, flatness, gouges, holes, improper

bends, kinks, sharp dents, splits, swelling, or

wrinkles in an SMDC or FCDC assembly.

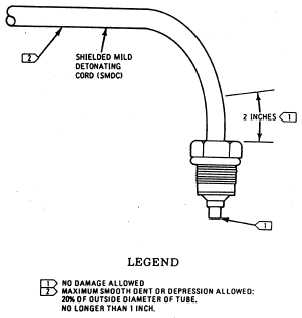

5. Smooth dents or slight depressions in

SMDC or FCDC assemblies, tubing, or hoses are

permitted if they do not exceed specified damage

limits (fig. 2-20). If the limits are exceeded, the

SMDC or FCDC assembly must be replaced.

Figure 2-20.—SMDC damage limits.

2-27