aircraft structure to maintain cockpit pres-

surization. The system, using cooled engine

bleed air from the air-conditioning system,

inflates the canopy seal in response to

movement of the canopy locking linkage.

The system deflates the seal when the can-

opy is unlocked. There are many different

types/designs of pressure-maintaining seals

used on naval aircraft. The main difference

between canopy seal systems is the type

of canopy seal pressure regulator used, elec-

trical or mechanical. The F-14 inflatable

seal will be discussed in the following para-

graphs. The A-6 operates in a similar man-

ner, but will not be covered in detail here.

Refer to maintenance manuals for specifics.

SYSTEM OPERATION

The canopy seal pressure regulator receives

cooled engine bleed air, at approximately 80 psi,

from the service air heat exchanger. When

the canopy is closed and locked, the regulator

plunger is released; this opens the shutoff

valve. Air from the regulator inlet then flows

past the check valve and shutoff valve, through

the outlet port, and to the canopy inflatable

seal. As air pressure in the seal increases,

pressure buildup in the regulator chamber

moves the bellows seat away from the flange.

The interior of the bellows is vented to

ambient. When pressure in the seal reaches

25±5 psi above ambient, the bellows will

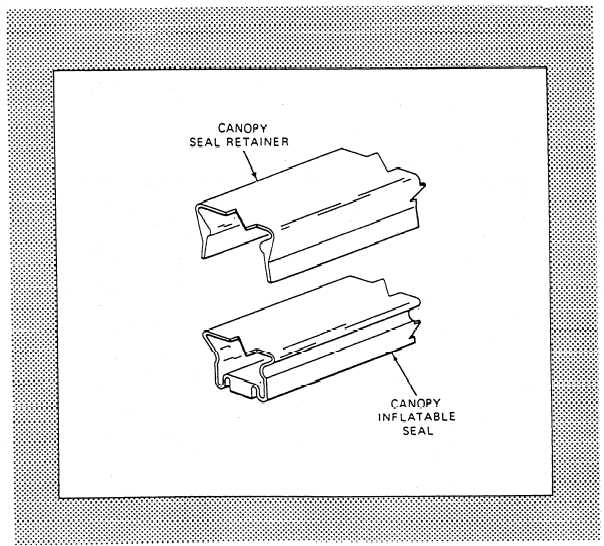

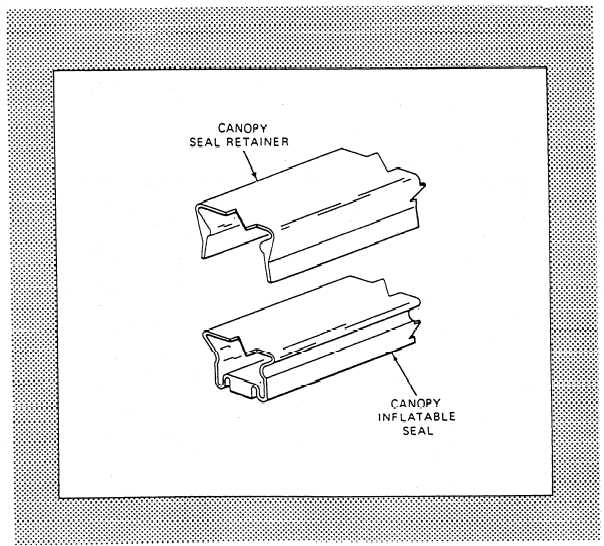

Figure 2-9.—Typical canopy inflatable seal (removed).

2-12