Once the parts have been properly cleaned, you

should inspect them for damage or wear and replace or

repair the parts as necessary. Before reassembling the

ejector mechanism, apply a light coat of general-

purpose preservative lubricating oil (VV-L-800). To

prevent the piston from locking up, you must wipe off

all the excess oil.

For further information concerning the Aero 7A-5

and Aero 7B-4, refer to the publication Ejector Rack

Assembly Model Aero 7A-5, NAVAIR 11-5D-20.

BRU-10A/B AND BRU-11A/A BOMB

EJECTOR RACKS

The BRU-10A/B and BRU-11A/A bomb ejector

racks are used to mount and sway brace a single

weapon/store or for a variety of multiple weapon/store

adapters. The BRU-10A/B bomb ejector rack is pylon

mounted on the wing stations of the A-7E aircraft. It is

part of the aircraft’s basic weapon/store suspension

system. It may also be weapons-rail mounted to the

F-14 aircraft fuselage. The BRU-11A/A bomb ejector

rack is pylon mounted on the wing stations of the S-3

aircraft. It is part of the aircraft’s basic weapon/store

suspension system.

BRU-10A/B Bomb Ejector Rack

The BRU-10A/B bomb ejector rack (fig. 10-15) has

four suspension hooks-two hooks spaced 14 inches

apart and two hooks spaced 30 inches apart. It carries

weapons/stores weighing up to 4,000 pounds. The

bomb ejector rack has the necessary electrical

connections, mechanical and electrical arming units,

ejection components, and the mechanical linkage for

safely suspending and ejecting weapons or stores.

Although the BRU-10A/B bomb ejector rack differs

from the bomb ejector racks previously discussed, the

basic principles of operation are the same, except for the

operations discussed in the following paragraphs. As

you read them, refer to figure 10-15.

A manual cocking bolt and a manual release bolt are

located on the forward left-hand side of the frame

assembly, Before you load a weapon or store, manually

cock the mechanical linkage by rotating the cocking

bolt. This places the linkage sears in a position to lock

the suspension hooks when they are moved to the closed

position. The suspension hooks may be released

(opened) by manually rotating the manual release bolt.

To prevent damage to the mechanical linkage, you must

remove the safety flag assembly (safety pin) before you

rotate either the cocking bolt or the release bolt.

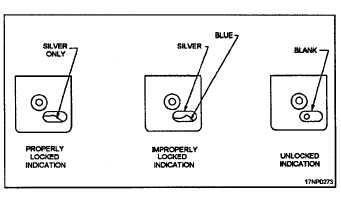

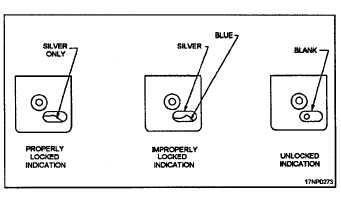

Figure 10-16.—BRU-10A/B bomb ejector rack hook latched

indicators.

To find out if the suspension hooks are properly

Iocked, you must visually check the latch inspection

holes (fig. 10-16) located in the frame assembly above

each hook. If the hook is properly locked, you can see

a silver latch indicator through the latching inspection

hole. If the hook is not locked, you can see a blue or

silver latch indicator. If the hooks are unlocked (open),

the latching inspection hole will be blank.

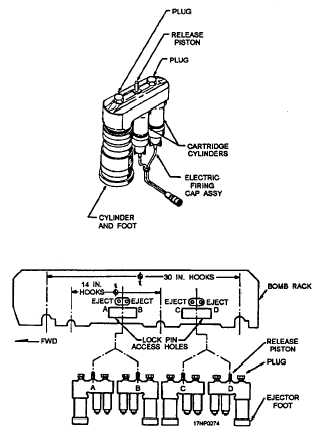

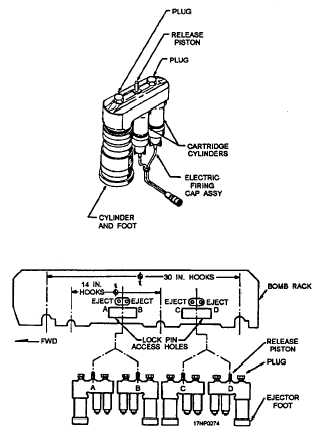

The BRU-10A/B bomb ejector rack is designed to

hold one ejector assembly that can be inserted in the

bomb rack in one of four different positions (fig. 10-17).

Figure 10-17.—BRU-10A/B bomb ejector rack ejector

assembly and installation positions.

10-13