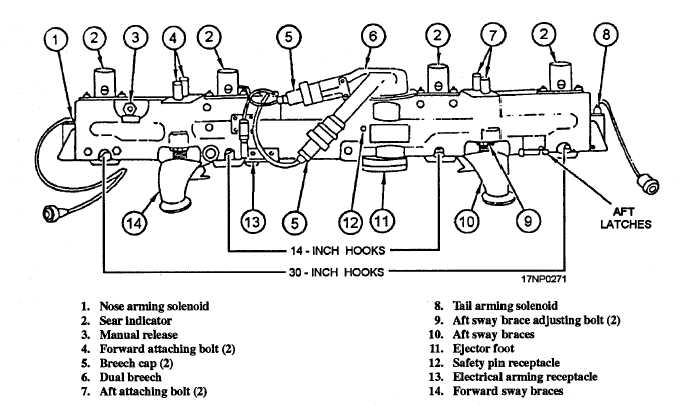

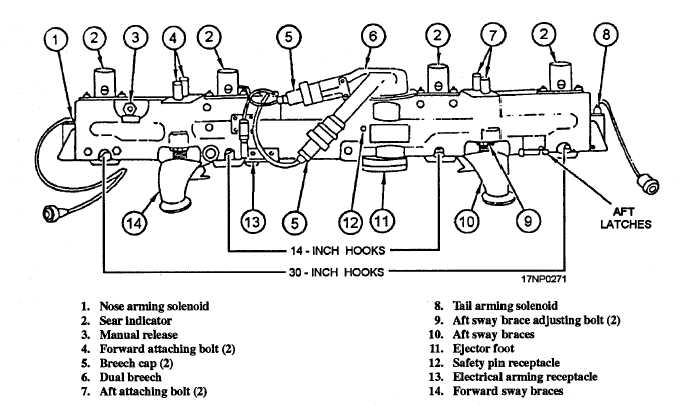

Figure 10-14.—Aero 7B-4 bomb ejector rack.

Principles of Operation

Operation of the bomb ejector rack is initiated when

28-volt dc is applied to the two impulse cartridges

installed in the dual breech assembly. The two impulse

cartridges are fired simultaneously, creating gas

pressure in the breech. Gas pressure buildup causes the

breech and sleeve assembly, through the mechanical

linkage, to raise the hook sears, which opens the

suspension hooks. At the same time, gas pressure is

applied to the piston assembly to drive the ejector foot

downward and eject the store from the bomb ejector

rack. After ejection, a spring in the sleeve assembly

returns the ejector foot to the sleeve housing.

Emergency operation of the rack is identical to normal

operation, except that completely separate electrical

wiring is used for each impulse cartridge to ensure

detonation of the two impulse cartridges.

Mechanical arming is done through the

electromechanical arming solenoids. It works in the

same manner as the Aero 65A series bomb racks. When

an armed drop is to be made by using electric fuzing, an

electrical signal is applied to the Mk 39 electric fuze

arming connector. When the hooks open, this signal is

transmitted to the Mk 122 Mod 0 safety arming switch,

which arms the weapon as it clears the rack suspension

hooks.

You don’t want the bomb ejector rack to fire during

ground operations. To prevent firing, insert a safety pin

into the safety switch assembly. The safety pin

maintains an open firing circuit, grounds the breech cap

assembly electrical circuit, and mechanically blocks the

linkage to prevent the suspension hooks from opening

manually. If the suspension hooks are opened manually,

remove the safety pin. If you rotate the manual release

nut with the safety pin installed, you will damage the

linkage and possibly shear a sear retainer pin. Once the

hooks are manually opened, you can reinstall the safety

pin to load weapons or stores.

Maintenance Requirements

Organizational-level maintenance for the Aero

7A-5 and the Aero 7B-4 bomb ejector racks is normally

performed while the bomb ejector racks are installed on

the aircraft. The exception is the 21-day special

inspection. In this case, the bomb ejector rack is

removed from the aircraft. The bomb ejector racks are

also removed from the aircraft and routed to an

intermediate-level maintenance activity every 420 days

for rework. They are removed from the aircraft every

42 months and routed to a depot-level maintenance

activity for overhaul.

Normally, routine maintenance at the organizational

level is performed during regularly scheduled servicing

10-11