PUMP LOGIC CALIBRATION

then to see the pulsations smoothed out by the filter. The

point where the signal stops or becomes distorted is the

One important and frequently performed task of the

place you should look for trouble.

GSE is to make sure the fuel oil and lube oil pumps cycle

Before you begin signal tracing, it is a good idea to

as designed. This action is called pump logic calibration.

measure the dc voltage. If you have no dc output voltage,

Pump logic calibration is accomplished according to

you should look for an open or a short in your signal

PMS. As a GSE, you must be able to recognize and

tracing. If you have low dc voltage, you should look for

correct any malfunctions that occur with pump logic.

a defective part. Keep your eyes open for the place

Your actions will help keep the engineering plant

where the signal becomes distorted.

operating at its maximum efficiency.

No matter what power supplies you may come

Each gas turbine-powered ship has different pump

across on the various classes of gas turbine-powered

logic settings. These differences are too numerous for

ships, they all do the same thing. They change ac voltage

us to cover in this TRAMAN. In this section, however,

i n t o usable dc voltage(s). For that reason, basic

we will discuss the basic elements of pump logic

troubleshooting and testing will be the same. Although

c a l i b r a t i o n . Remember, refer to the appropriate

technical manual for detailed descriptions of the proper

you may experience problems that have not been

covered specifically in this section, you should have

settings for fuel oil and lube oil pumps.

gained enough knowledge to localize and repair any

power supply problem that may occur.

PUMP LOGIC FUNCTION

During normal operation, the fuel oil booster pumps

ADJUSTMENTS

and lube oil pumps are automatically cycled by pump

control logic. They are cycled between off, slow, and

fast to maintain header pressure. Pump control logic will

Many console power supplies contain dc/dc

control the pumps to increase header pressure when

converters that require adjustment of their output levels.

pump output is inadequate to meet demand.

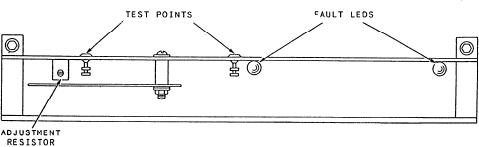

The adjustment variable resistor and the test points for

monitoring converter output are accessible when the

The cycling characteristics and pressures differ on

each class of ship. Fuel oil pump control logic prevents

power supply cover is removed. An example of a dc/dc

converter with test points, fault LEDs, and an output

loss of fuel to the gas engines by cycling the pump (or

adjustment resistor is shown in figure 5-33.

pumps) up to fast when the pressure drops. Sometimes,

fuel pump control logic cycles both pumps to stop if

Power supplies contain different types of de/de

pressure does not recover after a determined number of

c o n v e r t e r s . These converters vary only in their

seconds. This action prevents flooding of the engine

development of different outputs. The procedures for

room if a fuel leak develops.

a d j u s t i n g each converter will differ only in the

specification of the output level. When adjusting the

On some ships, the fuel pumps must be slowed or

converters of console power supplies, make sure they

stopped manually. Lube oil pump control logic prevents

are under normal load conditions. Some power supply

reduction gear damage by constantly providing positive

converters are wired in parallel pairs. Adjust these by

lube oil pressure to the gear. Pump logic usually cycles

alternately securing the power to one power supply,

the lube oil pumps up and down with respect to lube oil

while adjusting the other.

pressure.

Figure 5-33.--Power supply dc/dc converter.

5-43