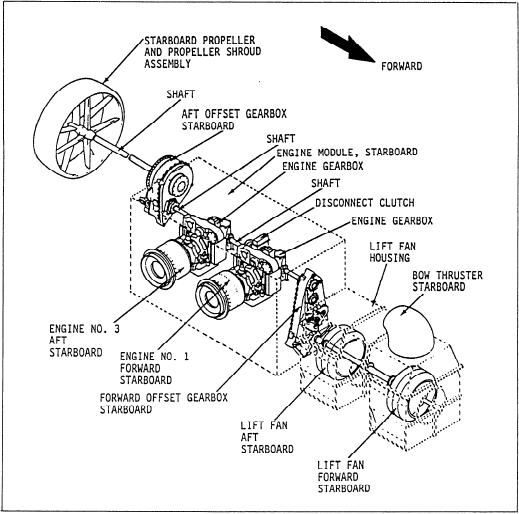

has one discharge volute directed upward to the bow

are driven by the TF40B gas turbine engines through

right-angle gearboxes, as illustrated in figure 7-11. The

thruster assembly.

lift fan control system uses the output of the TF40B

Solenoid-Operated Valves

engines, throughshafts, and reduction gears to turn the

fans that provide air to the cushion and the bow thrusters.

Four 4-way, 3-position solenoid-operated valves

Sixty percent of the air goes to the cushion and forty

a l l o w the engineer to control the cushion vanes.

percent goes to the bow thrusters. The air going to the

Momentary push-button switches located on the C&C

cushion can be increased or decreased by opening or

keyboard allow the operator to control these valves. (See

closing the four sets of cushion vanes. Let's take a look

fig. 7-12.) Each valve has an A and a B solenoid.

at the components of this system and how they work

Solenoid A energizes when the VANE CLOSE push

button is depressed. Solenoid B energizes when the

Lift Fans

VANE OPEN push button is depressed. Depressing the

push button allows hydraulic pressure to be applied to

As described earlier, there are two identical lift fan

the actuator, which causes the cushion vane to operate.

assemblies port and starboard. Each side has two

T h e s e valves have manual overrides in case an

double-discharge centrifugal fans, four air inlets, four

emergency occurs.

discharge ducts, and eight flow control vanes. Each air

inlet is protected by a foreign object damage (FOD)

Cushion Vanes

screen. Each fan is installed on an individual shaft.

These shafts are connected to each other and then to the

The function of the cushion vanes is to allow the

engineer to control the amount of airflow going to the

Figure 7-11.--TF40B propulsion and drive system arrangement.

7-9