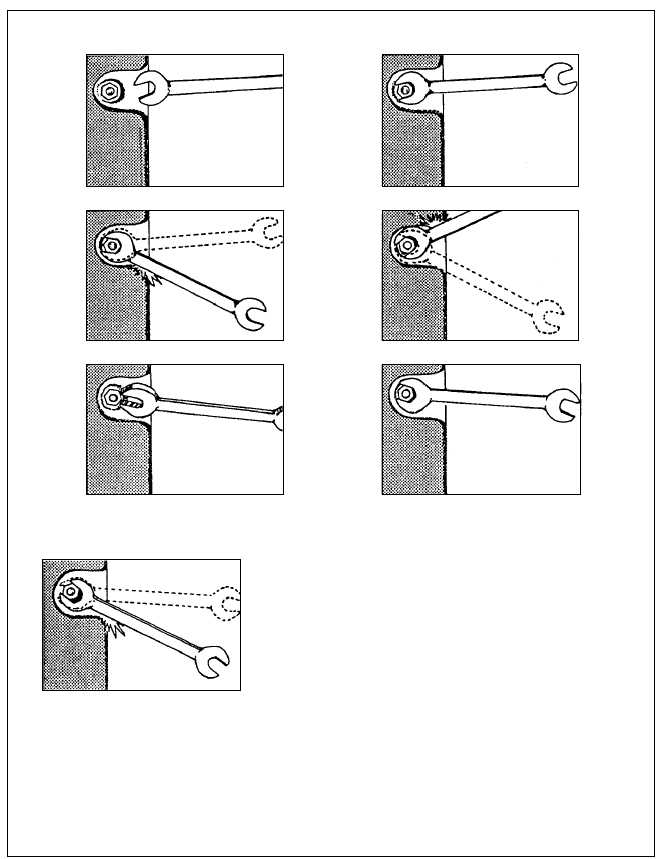

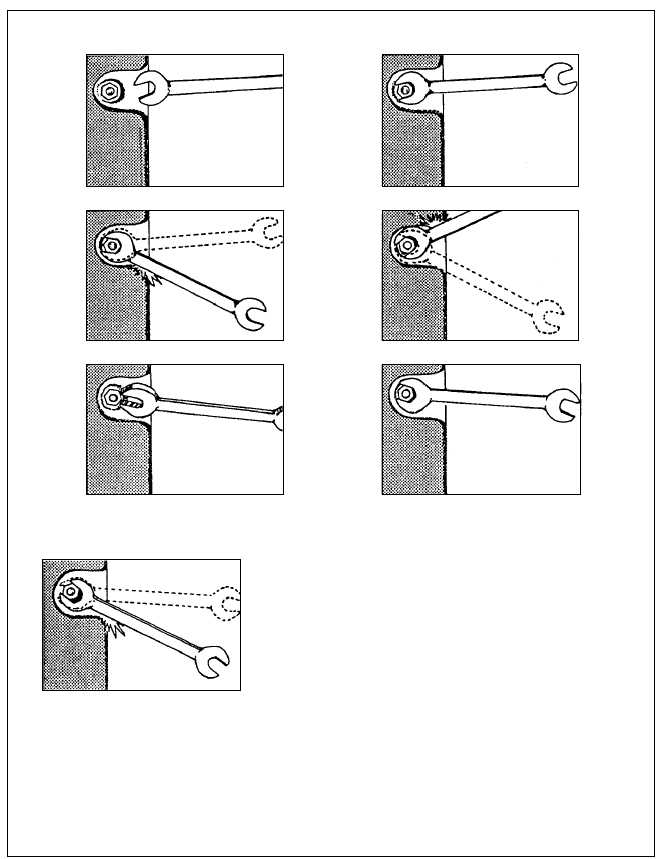

1-20

1. WRENCH, WITH OPENING SLOPING TO THE LEFT, ABOUT TO

BE PLACED ON NUT.

2. WRENCH POSITIONED AND READY TO TIGHTEN NUT. NOTE

THAT SPACE FOR SWINGING THE WRENCH IS LIMITED.

3. WRENCH HAS BEEN MOVED CLOCKWISE TO TIGHTEN THE

NUT AND NOW STRIKES THE CASTING, WHICH PREVENTS

FURTHER MOVEMENT.

4. WRENCH IS REMOVED FROM NUT AND TURNED COUNTER

CLOCKWISE TO BE PLACED ON THE NEXT SET OF FLATS

ON NUT. BUT CORNER OF CASTING PREVENTS WRENCH

FROM FITTING ONTO THE NUT.

5. WRENCH IS BEING TURNED OVER SO THAT WRENCH

OPENING WILL SLOPE TO THE RIGHT.

6. IN THIS POSITION, THE WRENCH WILL FIT THE NEXT TWO

FLATS ON THE NUT.

7. WRENCH NOW IS PULLED CLOCKWISE TO FURTHER

TIGHTEN NUT UNTIL WRENCH AGAIN STRIKES CASTING.

BY REPEATING THE PROCEDURE, THE NUT CAN BE

TURNED UNTIL IT IS TIGHT.

1

2

3

4

5

6

7

ABEf0105

Figure 1-28.—Use of open-end wrench.