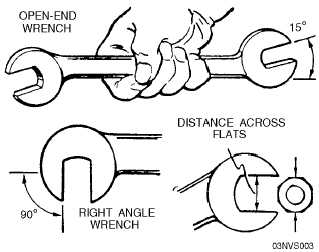

The size of any wrench used on bolt heads or nuts is

determined by the size of the opening between the jaws

of the wrench. The opening of a wrench is

manufactured slightly larger than the bolt head or nut

that it is designed to fit. Hex-nuts (six-sided) and other

types of nut or bolt heads are measured across opposite

flats (fig. 1-26). A wrench that is designed to fit a

3/8-inch nut or bolt usually has a clearance of from 5 to

8 thousandths of an inch. This clearance allows the

wrench to slide on and off the nut or bolt with a

minimum of "play." If the wrench is too large, the

points of the nut or bolt head will be rounded and

destroyed.

There are many types of wrenches. Each type is

designed for a specific use. Let's discuss some of them.

OPEN-END WRENCHES

Solid, nonadjustable wrenches with openings in

one or both ends are called open-end wrenches. (See

fig. 1-26.) Usually they come in sets of from 6 to 10

wrenches, with sizes ranging from 5/16 to 1 inch.

Wrenches with small openings are usually shorter than

wrenches with large openings. This proportions the

lever advantage of the wrench to the bolt or stud and

helps prevent wrench breakage or damage to the bolt or

stud. One exception exists.

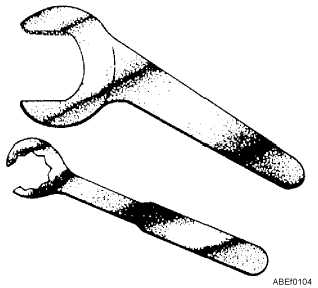

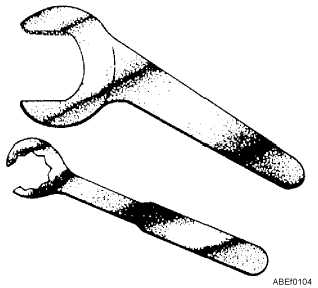

Hydraulic piping installations for catapult and

arresting gear are often in close spaces. During certain

phases of hydraulic maintenance it may be impossible

to swing an ordinary wrench because of its length.

Ordinary wrenches that are normally available increase

in length as their size increases. Thus, when a large-size

wrench is needed, the length of the wrench sometimes

prevents its use, due to the space available to swing the

wrench. The Bonney wrench, shown in figure 1-27, is

an open-end wrench that may be used to great

advantage because of its thickness and short length.

This wrench is normally procured in the larger sizes,

although it is available in a range of sizes to fit most

hydraulic fittings.

Open-end wrenches may have their jaws parallel to

the handle or at angles anywhere up to 90 degrees. The

average angle is 15 degrees (fig. 1-26). This angular

displacement variation permits selection of a wrench

suited for places where there is room to make only a

part of a complete turn of a nut or bolt. If the wrench is

turned over after the first swing, it will fit on the same

flats and turn the nut farther. After two swings on the

wrench, the nut is turned far enough so that a new set of

flats are in position for the wrench, as shown in figure

1-28.

Handles are usually straight, but may be curved.

Those with curved handles are called S-wrenches.

Other open-end wrenches may have offset handles.

This allows the head to reach nut or bolt heads that are

sunk below the surface.

1-19

Figure 1-26.—Open-end wrenches.

Figure 1-27.—Bonney wrenches.