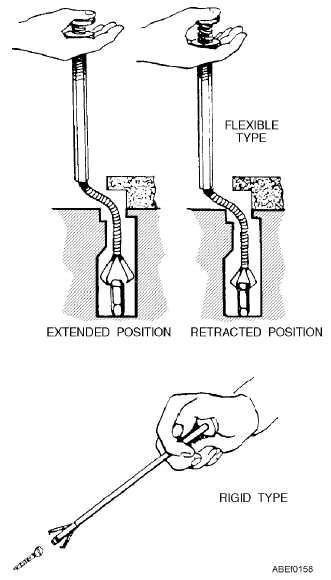

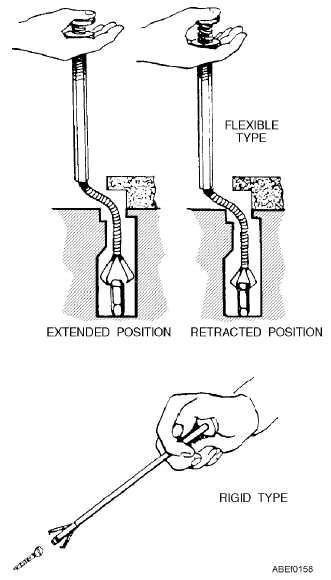

between the two plates holds them apart and retracts the

fingers into the tube.

With the bottom plate grasped between the fingers

and enough thumb pressure applied to the top plate to

compress the spring, the tool fingers extend from the

tube in a grasping position. When the thumb pressure is

released, the tool fingers retract into the tube as far as

the object they hold will allow. Thus, enough pressure

is applied on the object to hold it securely. Some

mechanical fingers have a flexible end on the tube to

permit their use in close quarters or around obstructions

(fig. 1-75).

NOTE

The fingers are made of thin sheet metal or

spring wire and can be easily damaged by

overloading.

REVIEW QUESTIONS

Q42.

What are mechanical fingers used for?

FLASHLIGHT

LEARNING OBJECTIVES: Identify the

type of flashlight that belongs in every toolbox.

Each toolbox should have a standard Navy

vaporproof two-cell flashlight. The flashlight is used

constantly during all phases of maintenance. Installed

in both ends of the flashlight are rubber seals, which

keep out all vapors. The flashlight should be inspected

periodically for these seals, the spare bulb, and colored

filters, which are contained in the cap.

NOTE

Do not throw away the filters; they will be

necessary during night operations.

REVIEW QUESTION

Q43.

Identify the type of flashlight that belongs in

every toolbox.

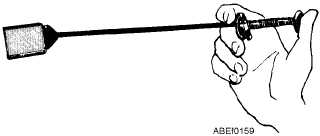

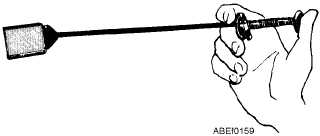

INSPECTION MIRROR

LEARNING OBJECTIVES: Describe the

use of inspection mirrors.

Several types of inspection mirrors are available for

use in maintenance. The mirror is issued in a variety of

sizes and may be round or rectangular. The mirror is

connected to the end of a rod and may be fixed or

adjustable (fig. 1-76).

The inspection mirror aids in making detailed

inspections where the human eye cannot directly see

the inspection area. By angling the mirror, and with the

aid of a flashlight, it is possible to inspect most required

areas. One model of inspection mirror features a

built-in light to aid in viewing those dark places where

use of a flashlight is not convenient.

1-47

Figure 1-76.—Adjustable inspection mirror.

Figure 1-75.—Mechanical fingers.