CHAPTER 2

MEASURING TOOLS AND TECHNIQUES

When performing maintenance and repair tasks on

catapults and arresting gear equipment, you must take

accurate measurements during inspection, to determine

the amount of wear or service life remaining on a

particular item or to make sure replacement parts used

to repair equipment meet established specifications.

The accuracy of these measurements, often affecting

the performance and failure rates of the concerned

equipment, depends on the measuring tool you use and

your ability to use it correctly.

COMMON MEASURING TOOLS

LEARNING OBJECTIVES: Identify the

different types of measuring tools. Describe

the uses of different types of measuring tools.

Describe the proper care of measuring tools.

You will use many different types of measuring

tools in the daily performance of your duties. Where

exact measurements are required, use a micrometer

caliper (mike). If you use the micrometer caliper

properly, it will allow you to measure within one

ten-thousandth (0.0001) of an inch accuracy. On the

other hand, where accuracy is not extremely critical, a

common straightedge rule or tape rule will suffice for

most measurements.

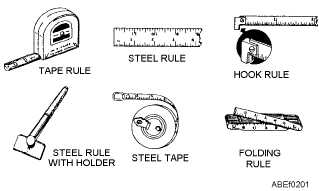

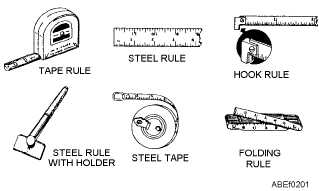

RULES AND TAPES

Figure 2-1 illustrates some of the commonly used

straightedge and tape rules. Of all measuring tools, the

simplest and most common is the steel or wooden

straightedge rule. This rule is usually 6 or 12 inches

long, although other lengths are available. Steel rules

may be flexible or nonflexible, but the thinner the rule

is, the easier it is to measure accurately with it, because

the division marks are closer to the work to be

measured.

Generally, a rule has four sets of graduated division

marks, one on each edge of each side of the rule. The

longest lines represent the inch marks. On one edge,

each inch is divided into 8 equal spaces, so each space

represents 1/8 inch. The other edge of this side is

divided into sixteenths. The 1/4-inch and 1/2-inch

marks are commonly made longer than the smaller

division

marks

to

facilitate

counting,

but

the

graduations are not normally numbered individually, as

they are sufficiently far apart to be counted without

difficulty. The opposite side of the rule is similarly

divided into 32 and 64 spaces per inch, and it is

common practice to number every fourth division for

easier reading.

There are many variations of the common rule.

Sometimes the graduations are on one side only,

sometimes a set of graduations is added across one end

for measuring in narrow spaces, and sometimes only

the first inch is divided into 64ths, with the remaining

inches divided into 32nds and 16ths.

Steel tapes are made from 6 to about 300 feet in

length. The shorter lengths are frequently made with a

curved cross section so that they are flexible enough to

roll up, but remain rigid when extended. Long, flat

tapes require support over their full length when

measuring, or the natural sag will cause an error in

reading.

MEASURING PROCEDURES

To take a measurement with a common rule, hold

the rule with its edge on the surface of the object being

measured. This will eliminate parallax and other errors

that might result because of the thickness of the rule.

Read the measurement at the graduation that coincides

with the distance to be measured, and state it as being so

2-1

Figure 2-1.—Some common types of rules.