Outside calipers for measuring outside diameters

are bow-legged; those used for inside diameters have

straight legs with the feet turned outward. Calipers are

adjusted by pulling or pushing the legs to open or close

them. Fine adjustment is made by tapping one leg

lightly on a hard surface to close them, or by turning

them upside down and tapping on the joint end to open

them.

Spring-joint calipers have the legs joined by a

strong spring hinge and linked together by a screw and

adjusting nut. For measuring chamfered cavities

(grooves) or for use over flanges, transfer calipers are

available. They are equipped with a small auxiliary leaf

attached to one of the legs by a screw (fig. 2-9). The

measurement is made as with ordinary calipers; then

the leaf is locked to the leg. The legs may then be

opened or closed as needed to clear the obstruction,

then brought back and locked to the leaf again, thus

restoring them to the original setting.

A different type of caliper is the hermaphrodite,

sometimes called odd-leg caliper. This caliper has one

straight leg ending in a sharp point, sometimes

removable, and one bow leg. The hermaphrodite caliper

is used chiefly for locating the center of a shaft, or for

locating a shoulder.

USING CALIPERS

A caliper is usually used in one of two ways. Either

the caliper is set to the dimension of the work and the

dimension transferred to a scale, or the caliper is set on

a scale and the work machined until it checks with the

dimension set up on the caliper. To adjust a caliper to a

scale dimension, hold one leg of the caliper firmly

against one end of the scale and adjust the other leg to

the desired dimension. To adjust a caliper to the work,

open the legs wider than the work and then bring them

down to the work.

CAUTION

Never place a caliper on work that is

revolving in a machine.

Measuring the Diameter of Round Stock or the

Thickness of Flat Stock

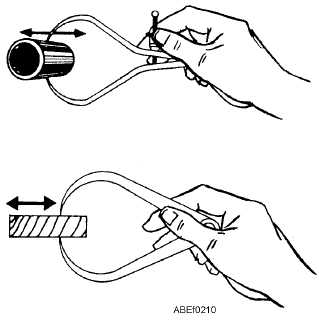

To measure the diameter of round stock or the

thickness of flat stock, adjust the outside caliper so that

you feel a slight drag as you pass it over the stock. (See

fig. 2-10.) After the proper "feel" has been attained,

measure the setting of the caliper with a rule. In reading

the measurement, sight over the leg of the caliper after

making sure the caliper is set squarely with the face of

the rule.

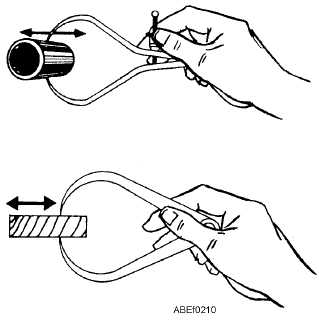

Measuring the Distance Between Two Surfaces

To measure the distance between two surfaces with

an inside caliper, first set the caliper to the approximate

distance being measured. Hold the caliper with one leg

in contact with one of the surfaces being measured.

(See fig. 2-11.) Then, as you increase the setting of the

caliper, move the other leg from left to right. Feel for

the slight drag indicating the proper setting of the

caliper. Then, remove the caliper and measure the

setting with a rule.

Measuring Hard-to-Reach Dimensions

To

measure

an

almost

inaccessible

outside

dimension, such as the thickness of the bottom of a cup,

use an outside transfer firm-joint caliper as shown in

2-5

Figure 2-10.—Using an outside caliper.

Figure 2-11.—Measuring the distance between two surfaces

with an inside caliper.