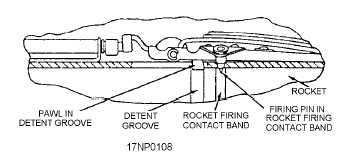

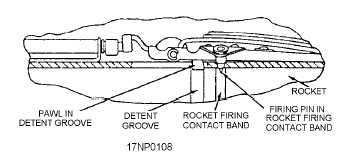

(fig. 2-18). When the rocket is loaded and unloaded, a

detent lift tool is used to raise and lower the detent pawl

by rotating the detent lift handle, which is located at the

forward end of the launcher. The detent also supports

the firing pin. Each firing pin (fig. 2-18) is part of the

detent assembly and is raised and lowered concurrent

with the pawl. The firing pin extends into the tube and

contacts the rocket firing contact band, which is located

aft of the rocket detent groove.

When the switch in the aircraft firing circuit is

closed, electrical current flows from the aircraft firing

circuit through the electrical receptacle, safety switch,

mode selector switch, intervalometer, and the firing pin

in the launcher to the contact band in the forward end of

the motor, and through the lead wire to the squib in the

igniter. The current entering the rocket squib heats the

squib primer mixture, which, in turn, ignites the igniter

charge.

Pressure within the igniter unseats a blowout plug,

permitting the burning charge to ignite the propellant

grain. The whole process of ignition requires about

0.005 second. Pressure of the hot propellant gases from

the burning grain bursts the nozzle seal and provides the

thrust to propel the rocket. Thrust overrides the detent

spring, releasing the pawl from the rocket detent

groove. The thrust then pushes the rocket out the

forward end of the tube. The impact from the first

rocket out shatters the forward fairing and the blast

removes the tail fairing.

2.75-INCH (SERIES) LAUNCHERS

The 2.75-inch (series) launchers are intended for

shipping (in some cases, with warheads installed)

stowing, and firing the 2.75-inch rockets. The weight of

loaded launchers varies, depending upon the number of

rockets installed and rocket configuration.

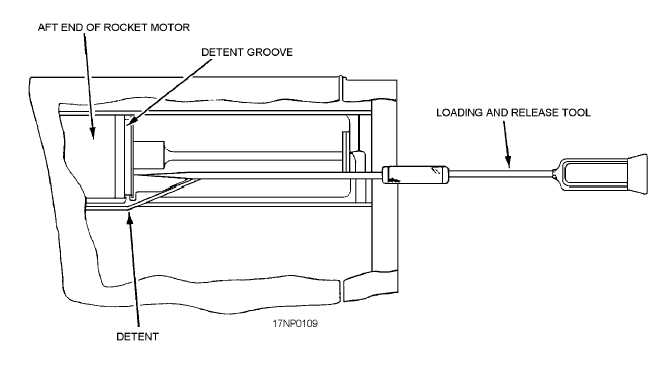

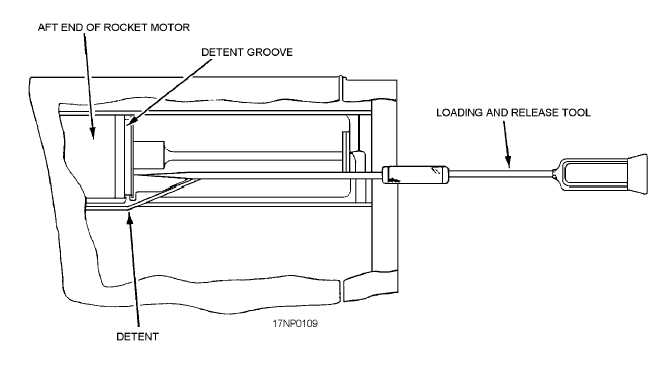

The rockets are retained in the launcher tubes

during shipping, handling, and flight by engagement of

a leaf-spring type of detent with integral blast paddles

(fig. 2-19). During loading, the rocket motor depresses

the detent until the detent snaps into the detent grooves

located on the aft end of the motor. To remove rocket

motors, use a rocket loading and release tool to depress

2-18

Figure 2-18.—LAU-10 (series) detent pin and firing pin

assembly.

Figure 2-19.—Rocket launcher detent (2.75-inch).