banding straps and the top section of the metal pallet,

the shipping cap on the rear of the bomb body, and all

plastic shipping plugs from the fuze cavities. Then,

install hoisting bars, as necessary, for manual handling

of the bombs. Other suitable hoisting equipment may

be used when available. Finally, place the bomb on the

appropriate bomb skid or assembly stand.

INSPECTION.—You need to inspect the bomb

for damage, stripped threads, cracks, or broken welds.

Make sure the bottoms of the suspension lug eyes are

flush with the weapon surface. Check to see that the

bomb's V-groove is clean and undamaged. Check the

fuze wells to ensure they are clean and dry. If nose

elements and/or electric tail fuzes are to be used, check

the electrical connectors to ensure they are not bent or

corroded. Press gently with a wooden dowel on the

connectors to ensure that they are firmly seated. Inspect

thermally protected bombs for loose or chipped

coating. Bombs that are missing more than 15 square

inches of thermal coating in one spot are not considered

thermally protected and are restricted from issue to

aircraft carriers. Damaged or otherwise unserviceable

bombs should be disposed of by following current

directives.

Adapter Boosters

Install adapter boosters by using the procedures

discussed in the following text.

WARNING

Fuzing for the thermally protected GP/TP

bomb to obtain cook-off protection is

limited to Fuze M904E4 with thermally

13-3

Figure 13-2.—Weapon lug thread engagement.

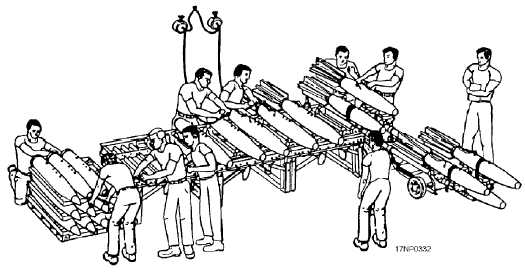

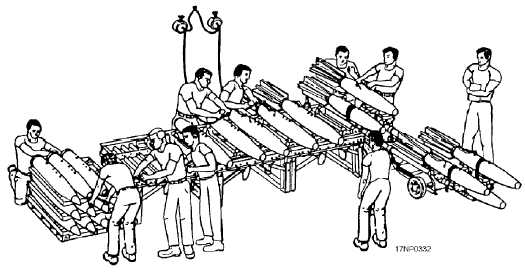

Figure 13-1.—Typical bomb assembly crew positions.