5. The motor contact bands, motor tube threads,

and nozzle and fin assembly must be clean and

free of grease or other lubricants.

6.

Check threads for damage or corrosion.

Assembly of Rocket Components

Rocket components are assembled as discussed in

the following steps:

WARNING

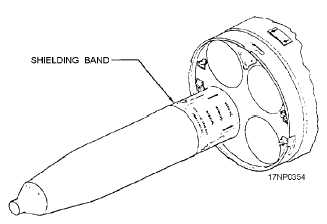

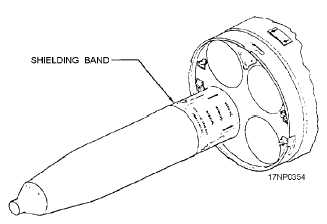

Ensure launcher is grounded. Shielding

bands must be in place whenever the rocket

motor is out of or protrudes from the

launcher. Ensure the shielding band covers

the contact band but does not touch it.

1.

Place detent lift arm in load position.

2.

Push forward on aft end of rocket motor until

forward end of rocket emerges from launcher.

3.

Slide shielding band (fig. 13-23) over motor

and hold against forward part of launcher; push

motor forward until locking tabs seat in the

motor detent grooves and not in the contact

band groove.

NOTE: A standard rocket assembly tool kit

containing

crowfoot

wrenches,

a

torque

wrench,

detent

locking

wrenches,

chain

wrenches, and strap wrenches is available for

the assembly of 2.75-inch and 5.0-inch rockets.

4.

Hold motor with strap wrench. Screw warhead

into motor and tighten securely with chain

wrench until the warhead seats 360 degrees.

5.

Attach appropriate nose fuze and tighten.

6.

Push rocket motor slowly into the tube until aft

end contacts aft stop.

7.

Rotate detent lift arm to flare position.

8.

Push the motor forward hard; pawl will engage

groove with audible click indicating positive

engagement.

2.75-INCH AIRBORNE ROCKET ASSEMBLY

PROCEDURES

Unpacking and inspection of the warhead, fuzes,

and motor are essentially the same as for the 5.0-inch

rocket components discussed earlier in this chapter.

Assemble rocket components as follows:

1.

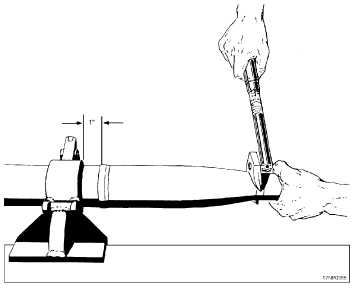

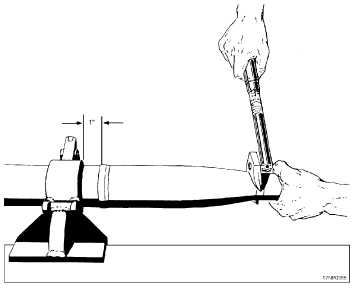

Place rocket motor body in holding fixture (fig.

13-24).

13-23

Figure 13-23.—5.0-inch rocket RADHAZ and electrostatic

protection.

Figure 13-24.—Holding fixture assembly.