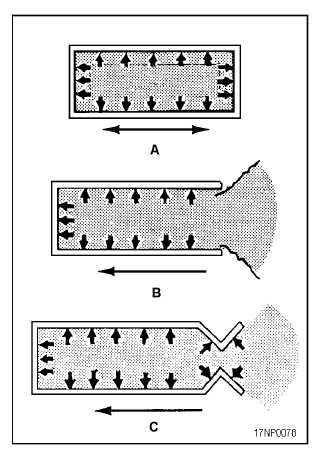

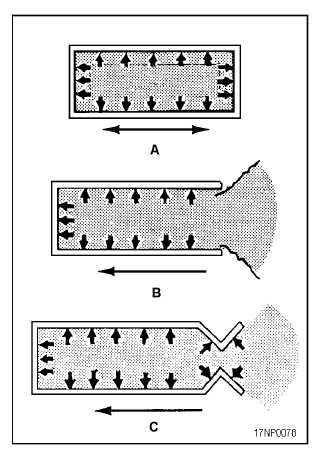

As you read this section, refer to figure 2-1. To

understand how a rocket operates, visualize a closed

container that contains a gas under pressure. The

pressure of the gas against all the interior surfaces is

equal (view A). If the right end of the container is

removed (view B), the pressure against the left end will

cause the container to move to the left.

In the rocket motor, gases produced by the burning

propellant are confined to permit a buildup of pressure

to sustain a driving force. A Venturi-type nozzle (view

C) restricts the size of the opening. The Venturi-type

nozzle decreases the turbulence of escaping gases and

increases the thrust. In this design, gas pressure inside

the container provides about 70 percent of the force,

and the escaping gases provide about 30 percent of the

force necessary to move the container forward.

ROCKET COMPONENTS

A complete round of service rocket ammunition

consists of three major components—the motor, the

warhead, and a fuze. A general description of these

components is given in the following paragraphs.

Motors

The rocket motor consists of components that

propel and stabilize the rocket in flight. Not all rocket

motors are identical, but they do have certain common

components. These components are the motor tube,

propellant, inhibitors, stabilizing rod, igniter, and

nozzle and fin assembly. The rocket motors discussed

in the following paragraphs are for the 2.75-inch Mk 66

Mods 2 and 4, and 5.0-inch Mk 71 Mod 0 and 1.

MOTOR TUBE.—The motor tube supports the

other components of the rocket. Presently, all motor

tubes are aluminum, threaded internally at the front end

for warhead installation, and grooved or threaded

internally at the aft end for nozzle and fin assembly

installation.

The Mk 66 Mods rocket motor tube is an integral

bulkhead type of motor tube and is impact-extruded

from aluminum stock. The forward end contains the

head closure and threaded portion for attachment of the

warhead. The integral bulkhead closure does not

rupture when accidentally fired without a warhead and

becomes propulsive when ignited. The center portion of

the motor tube contains the propellant. The nozzle and

fin assembly attaches to the aft end by a lock wire in a

grove inside the tube.

The Mk 71 Mods rocket motor tube is basically an

aluminum tube with an integral bulkhead closure. The

forward end contains the head closure, igniter contact

band, igniter lead, RAD HAZ barrier, and a threaded

portion for attachment of the warhead. The center

section is the combustion chamber and contains the

igniter, propellant grain, stabilizing rod, and associated

hardware. The aft end of the motor tube is threaded

internally to accept the nozzle and fin assembly.

PROPELLANTS.—The

propellant

grain

contained in the Navy's 2.75-inch and the 5.0-inch

rocket motors is an internal burning, star perforation,

double-base solid propellant. The star perforation is

designed to produce a nearly constant thrust level.

The Mk 66 rocket motor has the star points

machined off (conned) to reduce erosive burning.

INHIBITORS.—Inhibitors restrict or control

burning on the propellant surface. In the 2.75-inch and

the 5.0-inch motors, the propellant grains are inhibited

at the forward and aft ends, as well as the entire outer

surface. The forward and aft end inhibitors are molded

plastic (ethyl cellulose) components bonded to the

propellant ends. The outer surface inhibitor is spirally

2-2

Figure 2-1.—Principles of rocket propulsion.