bristle brush to remove caked dirt from exterior

staking tool. Verify the security of the bearing, and

inspect the area around the staking indentations for

surfaces. Use a piece of soft, copper wire to remove

possible fractures.

obstructions from ports and passages. Thoroughly dry

all parts with a clean, lint-free cloth or 20-psi

Many parts for the repair of the Gladden master

compressed air.

brake cylinder are provided in cure-date and overhaul

kits. Replace all other worn or damaged parts that

Inspection

cannot be reworked to meet inspection requirements.

Detail parts not provided in the kit may be available

Conduct the inspection of parts under a strong light

from bulk stock.

and preferably with a means of magnification. Make

the following checks:

Lubrication

1. Check all parts for nicks, cracks, scratches, and

Apply a light coat of hydraulic fluid to all sealing

corrosion.

devices to aid in reassembly. The recommended

2. Check threaded parts for crossed or damaged

lubricant for the suspension rod end bearing is grease,

threads.

Specification MIL-G-23827.

3. Check all packing grooves for surface defects

Reassembly

that might cut packings during installation or

cause failure during operation.

Reassemble all internal parts in reverse order of

4. Check the bearing on the suspension rod at the

disassembly by using an arbor press, or equivalent, and

reservoir port end of the cylinder for freedom of

an AN350-4 nut to aid in assembly and to eliminate the

rotation and evidence of flat spots.

possibility of personnel injury because of preload of

springs.

5. Check all springs for specified load at given

length. There should be no permanent set from

Testing

test loading, and springs should not wobble

when they are rolled across a flat surface.

The test equipment required includes a

c o nve n t i o n a l h y d r a u l i c t e s t b e n c h c a p a b l e o f

Repair and Replacement

delivering fluid to 4,500-psi pressure at room

temperature, plus the equipment illustrated in figures

Polish minor nicks and scratches on metal parts

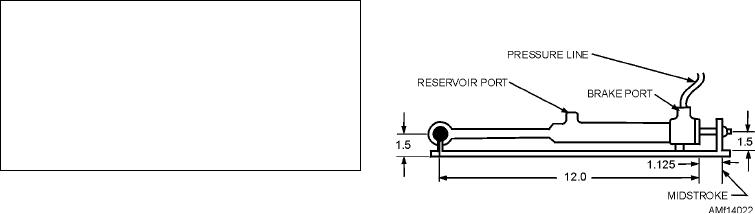

14-22 and 14-23. The nominal extended length of the

with crocus cloth (Federal Specification P-C-458C for

unit from the center of the end bearing to the end of the

steel parts and P-C-451B for aluminum parts). During

actuating rod is 15.31 inches.

polishing, make sure that all dimensions are

maintained within the specified limits and that seating

To proof test the inlet chamber and perform a

and sealing surfaces are not damaged.

leakage test, first apply 5 psi, and then 200 psi at the

reservoir port with the brake port plugged. There

Repair damage to anodized finishes on aluminum

should be no external leakage for 1 minute from either

parts by applying a protective chemical film per

port.

Specification MIL-C-81706, class 1A, Form III.

To perform the piston, valve, and brake chamber

WARNING

proof test, install the unit in the jig (fig. 14-22), and

Chemical film materials are strongly oxidizing

and are a fire hazard when in contact with organic

materials such as paint thinners. Do not store or mix

surface treatment materials in containers previously

containing flammable products. Rags contaminated

with chemical film material should be thoroughly

rinsed and disposed of as soon as practical.

When you replace a suspension bearing, stake the

new bearing at the original stake points on both sides of

Figure 14-22.--Piston, valve, and brake chamber proof test

the body by using a 3/16-inch-diameter ball in the

setup diagram

14-22