however, certain repairs that can be effected in case of

Reassembly

valve malfunction. These include replacement of

Before reassembly, immerse all internal parts in

seals, as required, tube, shaft, springs, or even the body

filtered, clean hydraulic fluid. Parts are reassembled

in more serious cases.

while they are still wet. Reassembly is accomplished

Tests are not required on the individual valve parts.

in the reverse order of disassembly. Upon completion

After disassembly, cleaning, inspection, repair or

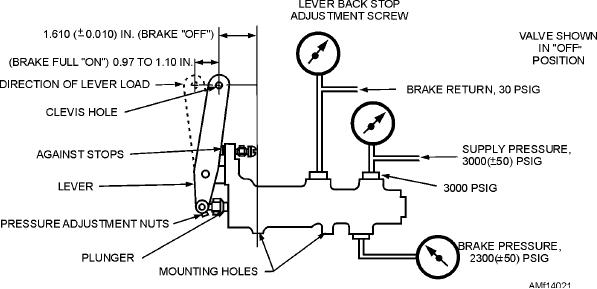

of reassembly, adjust the lever backstop adjustment

replacement, lubrication, and complete reassembly

screw to the dimensions indicated in figure 14-21.

have been accomplished, perform a bench test. This

test will determine whether the unit satisfies the

Testing

required minimum specifications.

Figure 14-21 shows the operational test setup used

Test the power/manual brake valves on a test bench

to accomplish the variety of tests required to verify that

before installation in the aircraft. The test bench must

the valve is ready for issue. A test stand capable of

be capable of supplying hydraulic fluid filtered

supplying hydraulic pressure from 0 to 4,500 psig

through a 3-micron filter at a maximum pressure of

pressure is required. Air is bled from the valve, and

2,250 psi. During the test the room temperature should

testing is conducted in accordance with the test

be 70 to 90F, and the fluid temperature 70 to 110F.

procedures table provided in the MIMs and/or 03

The bench test is divided into the manual section

manual. Tests include proof test, static pressure test,

and the power section. No particular sequence of

pressure drop test for internal leakage, and a complete

performance of bench test is required, except that the

operational test to verify power operation and

proof pressure test of a section must precede the

adjustment. A test troubleshooting table can be found

leakage test of that section. Bleed all air from the unit

in the "Intermediate Repair" section of most MIMs and

before it is tested.

03 manuals. Tables may be used to assist in isolating

causes for malfunctions that result from repair action.

Proof Pressure Test--Manual Section

After testing, fill the valve with preservative

hydraulic fluid and plug all ports. Lockwire the lever

For this test the valve shaft must be harnessed in

backstop adjustment screw, the plunger end cap, and

the midposition (1-inch plunger stroke), and the

the end plug in the manner recorded before

RETURN port must be plugged. Apply hydraulic

disassembly.

pressure of 2,250 psi to the BRAKE port. There should

be no evidence of external leakage, permanent

POWER/MANUAL BRAKE VALVE

distortion, failure, or malfunction of any part of the

valve.

There is no daily or routine maintenance required

PUMPING TEST.--To perform the pumping

on the power/manual brake valve other than a wipe

test, you should connect a reservoir to the RETURN

down of the exposed portion of the rod. There are,

Figure 14-21.--Operational test setup--power brake valve.

14-20