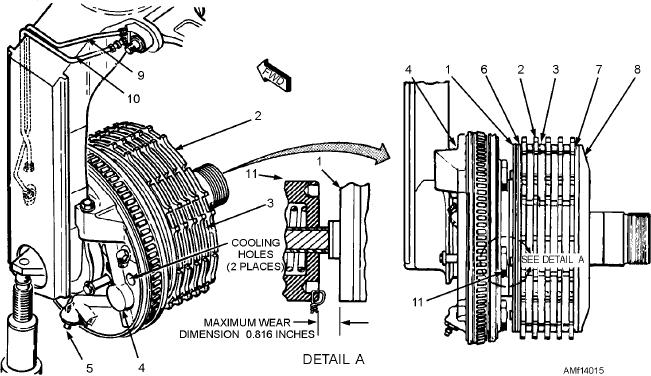

assembly (1) and the screw thread insert (11). See

Remove electrical power from the aircraft.

Depress the brake pedals several times to check

figure 14-15. Lining wear should not exceed 0.816

braking action. Place a bubble protractor on the brake

inch. Check running clearance by first applying the

pedals and adjust to zero when the brakes are in the

brake pedals until 1,200 psi is indicated on the gauges

OFF position. When the brakes are fully depressed, the

installed in the brake bleed ports. Measure the distance

protractor should indicate 30 degrees 1 degree, and

between the primary disc and the face of the screw

the hydraulic gauges on the brake assemblies should

thread insert. Release the brakes and measure the

indicate the same pressure as the external hydraulic

distance again. Subtract this dimension from that

power source.

obtained with the brakes applied to obtain the running

The external hydraulic power is shut down and

clearance. Clearance should be 0.070 to 0.119 inch.

system pressure is relieved by operating the rudder

pedals. Check brake accumulator action by fully

Brake Wear Check

depressing the brake pedals several times and checking

Lining wear may be checked by two methods.

the brake assembly action. Check the emergency brake

Before checking the brakes on any aircraft, always

system in the same manner as described for the

refer to the applicable MIM and use the method

operational checkout.

recommended by the aircraft manufacturer.

The next steps of the functional checkout require

that the wheel and tire assemblies be removed and

WEAR CHECK METHOD (NO. 1).--Have a

hydraulic power reapplied. Depress the brake pedals

person in the cockpit apply the brake, and with the

for approximately 1 minute, and check each power

brake applied, measure the distance between the face

plate for hydraulic leakage.

of the brake disc and the brake housing, as shown in

figure 14-16. If this distance has progressed to the

Check lining wear by depressing the brake pedals.

Measure the gap between the face of the primary disc

maximum specified measurement given in the MIM,

1.

Primary disc assembly

7.

Secondary disc insulation

2.

Rotors

8.

Secondary disc assembly

3.

Stators

9.

Pneumatic pressure line

4.

Power plate assembly

10.

Hydraulic pressure line

5.

Bleed valve

11.

Screw thread insert (5 each)

6.

Primary disc lining face

Figure 14-15.--Wheel brake.

14-15