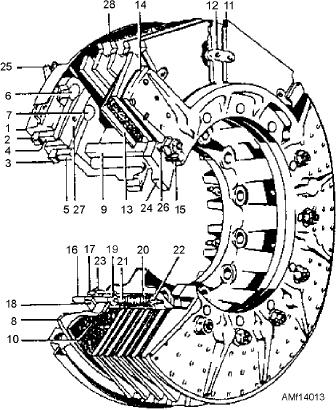

21. Adjuster sleeve

11. Rotor segment

1. Carrier assembly

22. Adjuster nut

12. Rotor link

2. Piston cup (outer)

23. Clamp holddown assembly

13. Stator plate

3. Piston cup (inner)

24. Shim

14. Backing plate

4. Piston (outer)

25. Bleeder screw

15. Torque pin

5. Piston (inner)

26.Drive sleeve bolt

16. Adjuster pin

6. Piston end (outer)

27.Dust cover (inner)

17. Adjuster clamp

7. Piston end (inner)

28.Dust cover (outer)

18. Adjuster screw

8. Pressure plate

19. Adjuster washer

9. Stator drive sleeve

20. Adjuster return spring

10. Auxiliary stator and lining assembly

Figure 14-13.--Segmented rotor brake--cutaway view.

GENERAL BRAKE SYSTEM

hydraulic power is slowly applied to the utility system.

The wheels should not rotate. By placing the landing

MAINTENANCE

g e a r h a n d l e t o t h e D OW N p o s i t i o n , i t s h o u l d

Proper functioning of the brake system is of the

illuminate the antiskid light and free the wheels to

utmost importance. Inspections must be performed at

rotate. The brake pedals should be fully depressed to

frequent intervals, and maintenance work must be

apply the brakes a minimum of three times.

performed promptly and carefully.

With external hydraulic and electrical power

Operational Checks

removed from the aircraft, operationally check the

emergency system by pulling the emergency brake

Prepare the aircraft for an operational checkout by

installing the landing gear down locks, jacking the

handle. The wheels should not rotate when the handle

aircraft to provide proper ground clearance for the

is pulled. Releasing the handle should immediately

landing gear, and applying external electrical power.

release the brakes. If any portion of the operational or

Placing the antiskid switch in the OFF position should

functional test does not meet the results specified in the

illuminate the antiskid warning light. When the

MIMs, refer to the trouble analysis sheets for the brake

landing gear handle is moved to the UP position, the

antiskid light should go out. At this point, external

system.

14-13