the brake should be removed and disassembled, and the

lining pucks inspected for wear.

NOTE: Linings can be measured only by

removing and disassembling the brake. If any puck has

worn to a thickness of less than one-sixteenth inch, the

entire set must be replaced. NEVER MIX NEW AND

USED LININGS.

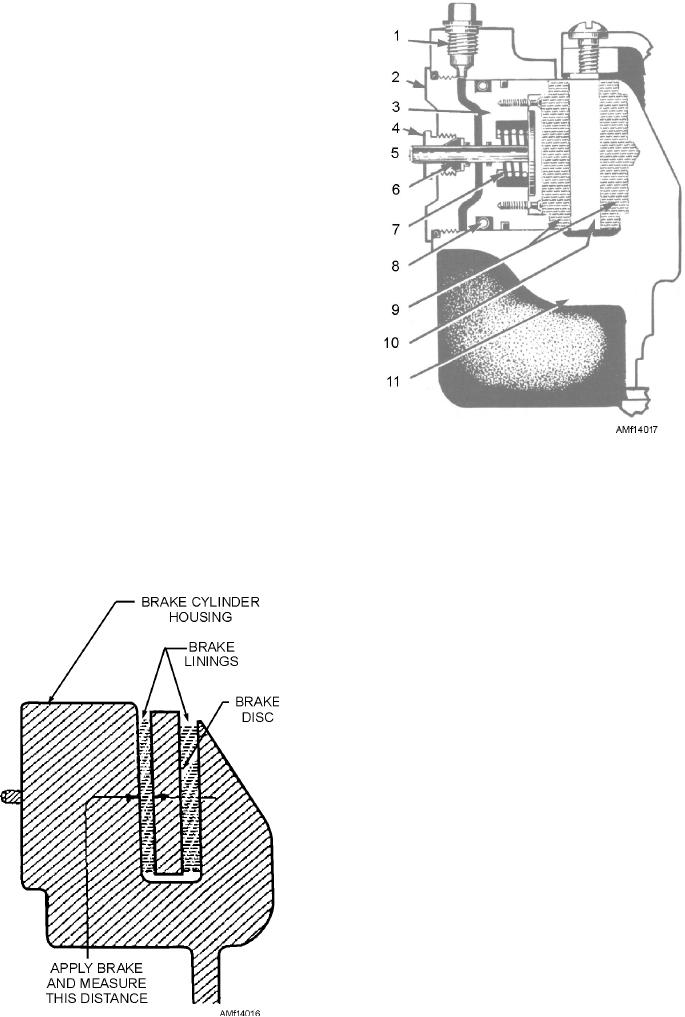

WEAR CHECK METHOD (NO. 2).--In using

this method, have a person in the cockpit apply the

brake. With the brake applied, check the position of the

automatic adjusting pins (fig. 14-17). If any adjusting

pin recedes inside the adjusting pin nut (one-sixteenth

to three-eighth inch, the exact amount depending on

the brake model), the brake must be removed and

disassembled, and the lining thickness checked. If any

lining is worn to a thickness of one-sixteenth inch or

less, the entire set of linings must be replaced. Figure

14-17 illustrates the normal position of the automatic

adjusting pin (protruding out of the adjusting pin nut).

Emergency System Contamination Check

1.

Brake fluid port

7.

Piston return spring

Check the emergency system for contamination.

2.

Cylinder head

8.

O-ring packing

Remove the plug from the unused pneumatic pressure

3.

Piston

9.

Brake lining

port on the brake assembly. Position a clean, white

4.

Adjusting pin nut

10.

Brake disc

cloth adjacent to the opening, and slowly pull the

5.

Automatic adjusting pin 11.

Brake lining

emergency brake control handle. Allow airflow

6.

Adjusting pin grip

through the system for approximately 5 seconds.

Figure 14-17.--Normal position of automatic adjusting pin.

T h e r e s h o u l d b e n o ev i d e n c e o f c o m bu s t i b l e

contaminants on the cloth. If the system is

contaminated, the emergency brake pneumatic lines

from the brake control valve to the brake assembly

must be flushed with a suitable solvent. Purge for a

minimum of 15 minutes with heated nitrogen.

Bleeding Procedures

There are two general methods of bleeding brake

systems--bleeding from top downward (top-down

method) and bleeding from the bottom upward

(bottom-up method). The method used generally

depends on the type and design of the brake system to

be bled. In some instances it may depend on the

bleeding equipment available.

T O P - D OW N M E T H O D . -- I n u s i n g t h e

top-down method, the air is expelled from the system

through one of the bleeder valves provided on the brake

assembly. See figure 14-18. A bleeder hose is attached

to the bleeder valve, and the free end of the hose is

Figure 14-16.--Checking lining wear (Method No. 1).

placed in a container that has enough hydraulic fluid to

14-16