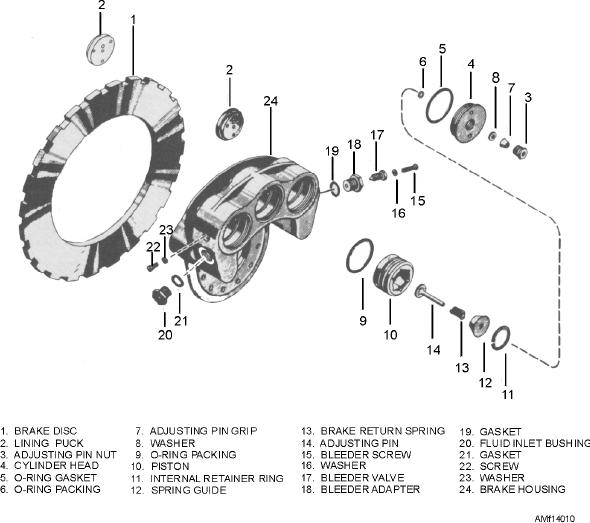

Figure 14-10.--Exploded view of single disc brake assembly.

the housing contains a piston, a return spring, and an

When pressure is relieved, the force of the return

spring is sufficient to move the piston away from the

automatic adjusting pin.

brake disc, but it is not enough to move the adjusting

There are six brake linings (pucks), three on the

pin, which is held by the friction of the pin grip. The

inboard side of the rotating disc and three on the

piston moves away from the disc until it stops against

outboard side of the rotating disc. These brake linings

the head of the adjusting pin, which provides a preset

are often referred to as "pucks." The outboard lining

clearance between the pucks and the disc. The

pucks are attached to the three pistons, and they move

self-adjusting feature of the brake will maintain the

in and out of the three cylinders when the brakes are

desired puck-to-disc clearance, regardless of lining

operated. The inboard lining pucks are mounted in

wear. Thus, regardless of the amount of wear, the same

recesses in the brake housing and are stationary.

travel of the piston will be required to apply the brake.

Hydraulic pressure from the brake control unit

Maintenance of the single disc brake may include

enters the brake cylinders and forces the pistons and

bleeding, performing operational checks, checking

lining wear, checking disc wear, and replacing worn

their pucks against the rotating disc. At the same time,

linings and discs.

the piston pushes against the adjusting pin (through the

spring guide) and moves the pin inboard against the

A bleeder valve is provided on the brake housing

friction of the adjusting pin grip.

(fig. 14-10) for bleeding the single disc brake.

Bleeding should be performed according to the

The rotating disc is keyed to the landing gear wheel

instructions contained in the aircraft MIM.

so that it is free to move laterally within the brake

cavity of the wheel. Thus, the rotating disc is forced

Operational checks are made during taxiing.

into contact with the inboard pucks mounted in the

Braking action for each main landing gear wheel

housing. This lateral movement of the rotating disc

should be equal, with equal application of pedal

pressure and without any evidence of soft or spongy

ensures equal braking action on both sides of the disc.

14-9