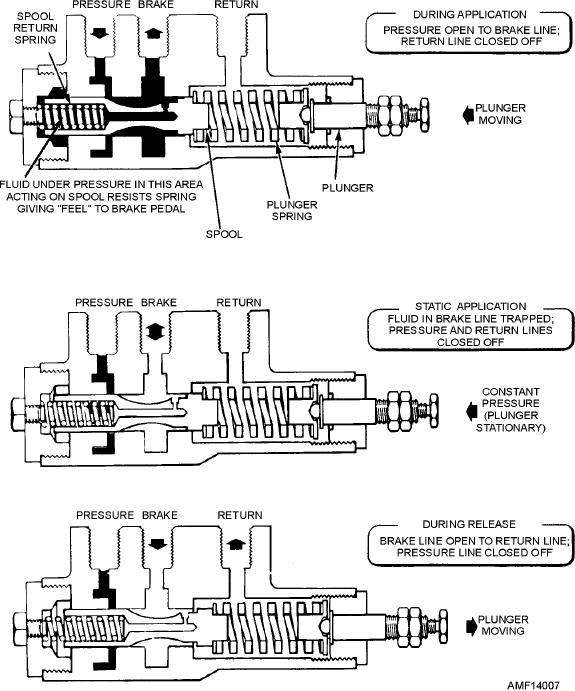

Figure 14-7.--Power brake control valve (sliding spool type).

Maintenance of the sliding spool brake control

power brake control valves. These units are generally

valve is limited to checking the action of the plunger.

used on aircraft equipped with a high-pressure

This is done by manually depressing the plunger until

hydraulic system and low-pressure brakes. The

it bottoms, and then releasing it suddenly. If the

purpose of the brake debooster cylinder is to reduce the

plunger remains depressed (does not snap out), the

pressure to the brake and increase the volume of fluid

valve is binding at the spool and sleeve. If binding

flow. Figure 14-8 shows a typical debooster cylinder

occurs, the valve should be replaced. Disassembly of

installation. The unit is being mounted on the landing

the valve is not permitted at the organizational level of

gear shock strut in the line between the control valve

maintenance, but may be performed by an intermediate

and the brake. The schematic diagram in the

or higher level activity.

illustration shows the internal parts of the cylinder.

When the brake is applied, fluid under pressure

Brake Debooster Cylinder

enters the inlet port to act on the small end of the piston.

The ball check prevents the fluid from passing through

In some power brake control valve systems,

the shaft. Force is transmitted through the small end of

debooster cylinders are used in conjunction with the

14-6