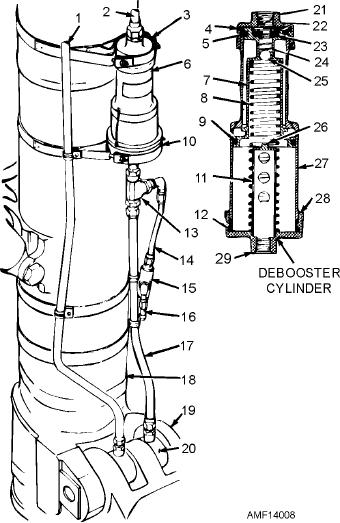

20. Brake shuttle valve

11. Riser tube

1. Emergency system pressure line

21. Inlet port

12. Packing

2. Main brake pressure line

22. Snapring

13. Tee fitting

3. Upper support clamp

23. Spring retainer

14. Brake line (to pressure relief valve)

4. Packing

24. Valve spring

15. Brake pressure-relief valve

5. Packing

25. Ball

16. Overflow line

6. Debooster cylinder assembly

26. Ball pedestal

17. Brake line (debooster to shuttle

7. Piston

27. Barrel

valve)

8. Piston return spring

28. Lower end cap

18. Shock strut

9. Packing

29. Outlet port

19. Torque link

10. Lower support clamp

Figure 14-8.--Brake debooster cylinder.

(due to a loss of fluid from the brake unit or connecting

the piston to the large end of the piston. As the piston

lines), the piston will continue to move downward until

moves downward in the housing, a new flow of fluid is

the riser unseats the ball check valve in the hollow

created from the large end of the housing through the

shaft. With the ball check valve unseated, fluid from

outlet port to the brake. Because the force from the

the power control valve will pass through the piston

small piston head is distributed over the greater area of

shaft to replace the lost fluid. Since the fluid passing

the large piston head, pressure at the outlet port is

through the piston shaft acts on the large piston head,

reduced. At the same time, a greater volume of fluid is

the piston will move up, allowing the ball check valve

displaced by the large piston head than that used to

to seat when pressure in the brake assembly becomes

move the small piston head.

normal.

Normally, the brake will be fully applied before the

When the brake pedal is released, pressure is

piston has reached the lower end of its travel. However,

removed from the inlet port, and the piston return

if the piston fails to meet sufficient resistance to stop it

14-7