Rigging

To adjust the steering amplifier, proceed as follows:

1. Insert rigging pin No. 1 in rudder pedal

Rigging of the control linkages consists of several

linkage, and check to see that rudder is in neutral.

steps. You must jack the nose of the aircraft and operate

the rudder pedals to deplete hydraulic pressure. Center

2. Operate the steering switch and check to see

the recoil strut manually so that the link arm is in line

that gear centers within 2 degrees of center index mark.

with the centers of the strut and the steering assembly.

3. If gear does not center within limits, adjust the

Adjust all lower links to move freely overcenter, to

steering amplifier potentiometer R7 so that the circuit

make sure that parts are free from binding, and then

balances.

lock in place with the stops. Install rigging pins in the

4. Remove rigging pin and check the area for

rudder pedal to nose steering assembly linkages.

foreign objects.

Adjust the rods to accommodate the installation of

the pins. Following adjustment of the linkage, remove

5. Remove the jack and external power.

the rigging pins and check the system for proper

NOTE: AE personnel normally accomplish the

operation.

electrical adjustments.

Steering Assembly Maintenance

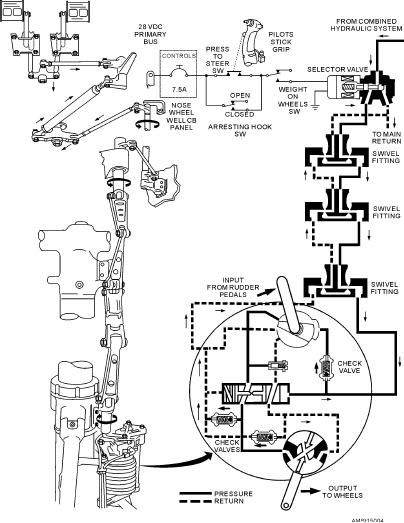

MECHANICALLY CONTROLLED NOSE

STEERING SYSTEM MAINTENANCE

O-rings, packings, and miscellaneous parts within

the steering assembly can be replaced at the

Maintenance of mechanically controlled nose

intermediate level of maintenance. Trouble analysis

steering systems closely parallels the maintenance

charts are in many of the MIM and 03 manuals. The

of electrically controlled nose steering systems.

charts accommodate the systematic checkout of

Mechanically controlled nose steering system mainte-

individual components. Like the aircraft trouble-

nance consists of the rigging and steering assembly

shooting charts, they are based on manufacturer's

maintenance. See figure 15-4.

experience, past part discrepancies, and part design.

Figure 15-4.--Nosewheel steering system.

15-5