maintenance requirements for the proper

to verify proper operation both hydraulically and

operation of the skid control system.

electrically.

Trouble analysis/troubleshooting of the antiskid

An antiskid test set is available for personnel in the

system is generally accomplished by personnel of the

AE rating to use on the antiskid system. The

AE rating. The steps provided for using the antiskid

operational test normally requires a joint effort on the

test set will pinpoint the causes for most malfunctions.

part of both AM and AE rated personnel.

Those steps that do not meet the specified results are

Organizational maintenance on the antiskid

investigated, parts are replaced as necessary, and the

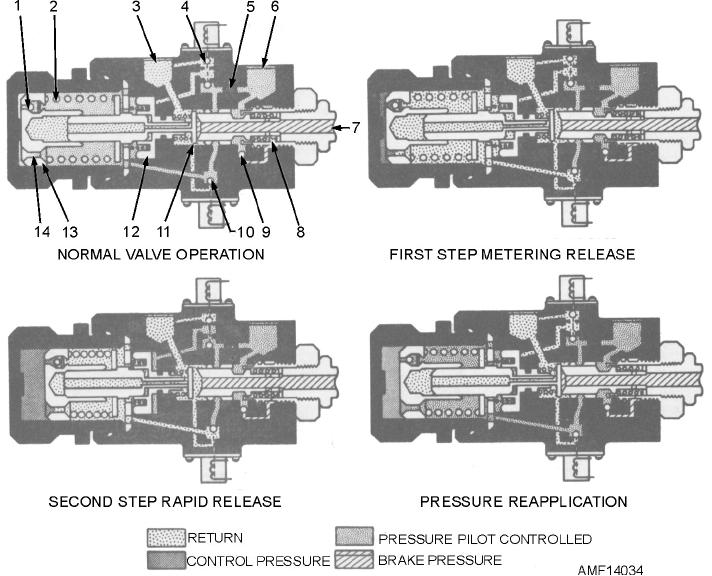

control valve, shown in figure 14-34, is limited to

complete operational check is repeated to verify that

removal and replacement. Intermediate level repair

the malfunction has been corrected.

of the valve consists of cure-date seal and parts

replacement in accordance with the procedures

Q14-36. What rating is generally responsible for

provided in the "Intermediate Maintenance" section

troubleshooting and trouble analysis of the

of the MIM. Following repair, the valve must be tested

antiskid system?

1.

Control orifice No. 2 (release)

8.

Poppet

2.

Control spring

9.

Ball check

3.

Return

10.

First step solenoid pilot valve

4.

Second step solenoid pilot valve

11.

Return seat

5.

Filter

12.

Release piston

6.

Pressure

13.

Control piston

7.

Brake

14.

Control orifice No. 1

Figure 14-34.--Antiskid control valve schematic.

14-37