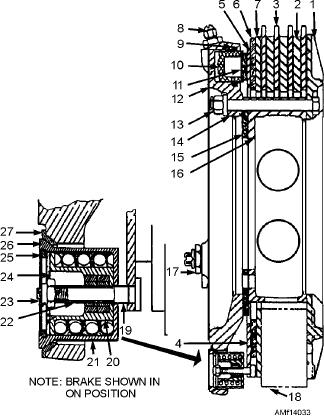

1.

Housing backplate

10.

Piston

19.

Self-adjusting pin

2.

Stationary discs

11.

Piston insulator

20.

Return-spring guide

3.

Rotating discs

12.

Brake housing subassembly

21.

Return spring

4.

Pressure plate subassembly

13.

Self-locking nut

22.

Self-adjusting pin tube

5.

Pressure plate

14.

Brake assembling bolt

23.

Self-locking nut

6.

Wear plate insulator

15.

Torque tube spacer

24.

Split collar grips

7.

Wear plate

16.

Keyed torque tube

25.

Retaining ring

8.

Bleeder valve

17.

Inlet bushing

26.

Spring housing

9.

O-ring and backup ring

18.

Self-adjusting mechanism

27.

Spring housing bushing

Figure 14-33.--Trimetallic brake assembly--cross section.

against the discs and against the housing backplate. As

discs. When pressure is removed from the brake, the

return springs return the pressure plate and the brake

the pressure is applied and the brake starts to actuate,

pistons to the designed reset clearance and maintain a

the lateral movement of the pressure plate

constant displacement.

subassembly pulls the self-adjusting pins, the split

collar grip and tube subassemblies, and the return

Maintenance

spring guides against the return springs, compressing

them until the spring guides bottom in the housings.

Intermediate maintenance of the trimetallic brake

When the hydraulic pressure is relieved, the return

assembly consists of disassembly, cleaning and

spring mechanisms, acting through the heads of the

inspection, wear pad replacement as necessary,

self-adjusting pins, pull the pressure plate

reassembly, and testing.

subassembly back to the released position. The pistons

DISASSEMBLY.--Place the brake assembly

also return to their deactuated positions. The extent of

with the brake housing down and remove the brake

the return motion is limited by engagement of the

housing bolts. Remove the backing plate and all discs

spring guides with the retaining ring stops inside the

spring housing.

Turn the brake over and remove the self-locking nuts to

As the discs wear, self-adjusting pins and tubes are

release the return pins. Remove the tube and grip

pulled through the split collar grips by the force exerted

assemblies, pressure plate, and the remaining return

on the pressure plate by the pistons. This small

spring parts. The tube and grip assemblies should not

movement of the adjusting pins and tubes, relative to

be disassembled. If they require replacement, replace

the grips, is equivalent to the combined wear of all the

the complete assembly as a unit.

14-35