pins of the self-adjusting mechanism, and rests against

the insulators installed in the outer ends of the brake

pistons. It is the component through which force is

directly transmitted during application and release of

the brakes. The wear plate is keyed to the torque tube to

prevent rotation of the complete subassembly, and

serves as the friction surface for the outer face of the

adjacent rotating disc. The wear plate insulator

prevents brake heat from being transferred to the

pressure plate and the brake pistons.

The brake pistons transmit hydraulic pressure

through the pressure plate subassembly to the brake

discs. Standard O-rings and backup rings around each

piston prevent hydraulic fluid leakage and entry of

contaminants. The pistons are further protected against

heat transfer from the pressure plate subassembly by

individual insulators installed in the ends of each

piston where it contacts the pressure plate.

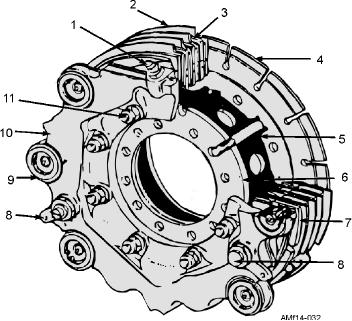

1.

Bleeder valve

7.

Pressure plate subassembly

Self-adjusting mechanisms are located around the

2.

Rotating disc

8.

Brake inlet port

brake housing. They accomplish normal release of the

3.

Stationary disc

9.

Self-adjusting mechanism

brake and provide a continuing adjustment action to

4.

Housing backplate

10.

Brake housing subassembly

compensate for brake wear. Each mechanism consists

5.

Keyed torque tube

11.

Brake assembling bol

of a self-adjusting pin, a spring housing and bushing, a

6.

Torque tube spacer

return spring guide, a retaining ring, a grip and tube

subassembly, and a self-locking nut. The grip and tube

Figure 14-32.--Trimetallic brake assembly.

subassembly mounts over the self-locking pin, with the

grips being installed firmly on the tube. As disc wear

occurs, automatic adjustment is provided by

Description

movement of the adjusting pins through the split collar

The brake housing subassembly, keyed torque tube

grips. The retaining ring inside the spring housing

and spacer, and the housing backplate are bolted

serves as a stop and retainer for the spring guide,

together to form the basic brake assembly. The

which, in turn, holds the return spring in position. The

head of the self-adjusting pin engages the pressure

remaining components of the brake assembly are

plate subassembly to allow brake release when

mounted over the keyed torque tube and between the

pressure is removed.

brake housing and the housing backplate. The

metallic-faced rotating discs have keyways that engage

Operation

drive keys in the wheel so that they rotate with the

wheel.

When the landing gear wheel is rotating, the

The rotating discs are separated by the stationary

metallic-faced rotating discs of the brake assembly

discs, which are keyed to the torque tube. The mating

rotate freely between the stationary steel discs. When

surfaces of these rotating and stationary discs

pressure is applied to the brake assembly pistons, the

constitute the major friction-braking surfaces of the

rotating and stationary discs are forced together,

brake. Additional friction surfaces exist between the

creating friction between their surfaces. The amount

outer face of one rotating disc and the housing

of hydraulic pressure applied to the brake pistons is

backplate, and between the outer face of the rotating

controlled by the aircraft's brake metering system in

disc at the opposite end and the pressure plate

response to the operating of the brake pedals. Braking

subassembly.

action applied to the wheel brake is proportional to the

pressure exerted on the brake pedal.

The pressure plate subassembly consists of the

pressure plate, replaceable wear plate, and wear plate

Pressure applied to the brake actuates all of the

insulator. These three parts are riveted together. The

pistons within the brake housing. These pistons, in

pressure plate serves as a seat for the self-adjusting

turn, force the pressure plate subassembly laterally

14-34